What Are Specialty Fibers and Why Are They Transforming Modern Materials?

Specialty fibers—defined by their unique composition, structure, or functionality—are revolutionizing modern materials across industries due to their advanced performance and versatile applications.

What Are Specialty Fibers and Why Are They Transforming Modern Materials?

Introduction

Specialty fibers—defined by their unique composition, structure, or functionality—are revolutionizing modern materials across industries due to their advanced performance and versatile applications. Unlike conventional fibers such as cotton or basic synthetics, specialty fibers are engineered to deliver specific mechanical, thermal, optical, or ecological advantages. From aerospace-grade composites to biodegradable fashion innovations, specialty fibers are reshaping how we design, build, and wear the world around us.

Today, with heightened demands for sustainability, performance, and smart functionality, specialty fibers have emerged as key enablers for next-generation materials. Let’s explore what defines them, how they’re pushing boundaries, and why they matter now more than ever.

1. What Defines a Specialty Fiber?

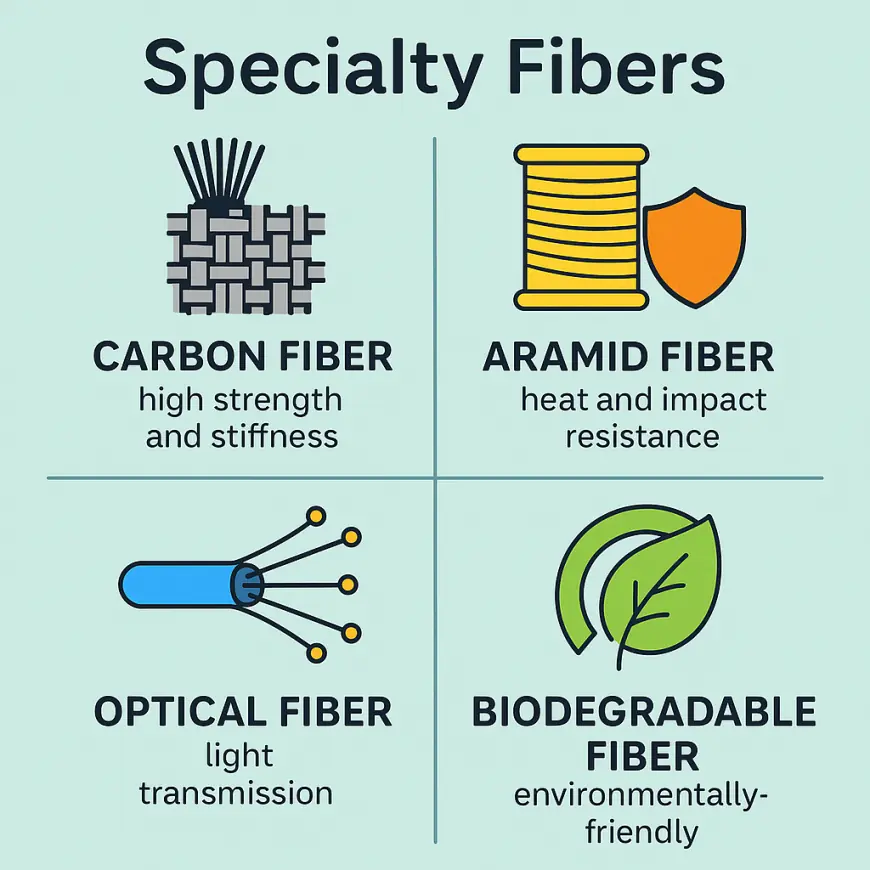

Specialty fibers are distinguished by their tailored properties, achieved through controlled material composition or structure. These differences may include:

-

Optical specialty fibers—such as active fibers doped with rare-earth ions, double- or triple-clad variants for enhanced light handling, radiation-resistant fibers for space applications, and fibers with engineered dispersion or nonlinearity.

-

High-performance engineering fibers, including:

-

Aramid fibers (e.g., Kevlar, Nomex) celebrated for heat resistance and strength in aerospace and body armor.

-

Silicon carbide fibers, known for high stiffness, tensile strength, thermal resistance, and chemical stability—popular in gas turbines, defense components, and electronics.

-

Boron fibers, offering unmatched strength-to-weight ratios, widely used in advanced aerospace components and sporting goods composites.

-

-

Textile-based specialty fibers, valued in construction, filtration, EMI shielding, medical, and electrostatic control domains.

-

Environmentally intelligent fibers, designed with advanced processing—like wet spinning, surface treatments, cyclization, heat treatment, or metal chelation—to enhance stability, performance, or biodegradability.

In essence, specialty fibers venture beyond basic function—they are engineered with purpose, precision, and performance at their core.

2. Why Specialty Fibers Are Transforming Modern Materials

2.1 Performance & Innovation Drivers

-

Aerospace & Defense: Silicon carbide and boron fibers are integral in high-temperature, lightweight composites for engines and armaments.

-

Safety & Protection: Aramid fibers underpin bullet-resistant gear and flame-retardant insulation due to exceptional thermal and mechanical resilience.

2.2 Smart & Optical Applications

-

Specialty optical fibers facilitate high-performance telecom systems, sensing, and medical diagnostics through precise dispersion, nonlinearity, and guiding properties.

-

E-textiles (electronic textiles) embed conductive or sensing fibers directly into fabric, enabling wearable computing, biosensing, and soft robotics.

2.3 Sustainability & Eco-Innovation

-

Biodegradable protein-based fibers aim to reduce textile pollution and dependence on plastics, with biotech innovators pushing for large-scale production by 2025.

-

Upcycled citrus peel fabric is emerging in fashion, yielding fibers with antibacterial, UV-protective, and thermoregulating properties.

-

Biomaterial experiments, such as seaweed-based fabrics or corn-derived synthetics, push industry norms, even if not yet mass-market.

2.4 Smart Textiles & Fashion Tech

-

Smart fabrics with moisture-wicking, thermoregulating, and antimicrobial traits are on trend as consumers demand wellness-friendly textiles.

-

Circular fashion technologies—including waterless dyeing and traceable, biodegradable materials—are rising in 2025's textile landscape.

-

Graphene-enhanced natural fiber composites combine sustainability with improved mechanical performance, as seen in lab-engineered jute composites.

3. 2025 Trends Driving the Specialty Fiber Revolution

3.1 Sustainability as a Baseline

In 2025, sustainability is no longer optional—it’s expected. Fiber innovations from upcycled biomaterials to closed-loop manufacturing are becoming key differentiators.

3.2 Smart Functionality

Textiles that adapt to body conditions—via moisture control, temperature regulation, or built-in electronics—are transforming performance wear and home interiors alike.

3.3 Traceability & Circular Design

Blockchain and localized artisanal production increase transparency and reduce waste—melding tradition with tech-forward supply chains.

3.4 Cross-Border Manufacturing Shifts

While Southeast Asia leads commodity fiber production, developed markets focus on premium, functional, and localized fiber technologies.

3.5 Market Dynamics

Despite growing applications, the specialty fibers market is projected to contract slightly, with a forecasted CAGR of –0.8% from 2025 to 2033, due to pricing pressures and shifting supply chains.

4. Spotlight: Real-World Applications

Luxury Meets Eco-Performance

Orange-fiber fabric brings an artisanal, sustainable flair to high fashion—combining form, comfort, and performance in one sustainable weave.

Biotech Meets Textiles

Protein-based fibers are designed to biodegrade and eliminate microplastic pollution—a promising leap toward sustainable fashion supply chains.

Experimental Biomaterials in Design

Seaweed, corn, and mushroom-leather experiments may not yet be scalable—but they are planting seeds for future breakthroughs in sustainable specialty fibers.

Conclusion

Specialty fibers are not niche—they're central to the evolution of modern materials. Whether pushing the limits of strength, enabling digital integration, or redefining sustainability, these fibers embody innovation grounded in real-world needs.

As 2025 unfolds, we see a clear narrative: performance, sustainability, and intelligence converge—with specialty fibers leading the way. The future of materials is flexible, functional, and increasingly conscious.

FAQ

Q1: What distinguishes specialty fibers from conventional fibers?

A: Specialty fibers are engineered for unique functions—not just basic comfort or cost efficiency. They may provide optical control, enhanced thermal resistance, smart sensing, or eco-innovation beyond what standard fibers deliver.

Q2: What are common types of specialty fibers?

A: Examples include aramid (e.g. Kevlar), silicon carbide, boron fibers, optical fibers with engineered cladding, e-textile conductors, and biomaterial fibers from proteins or plant upcycling.

Q3: Where are specialty fibers used?

A: They appear in aerospace engineering, medical devices, ballistic protection, telecommunications, wearable tech, high-performance fashion, sustainable textiles, and advanced composites across industries.

Q4: How are specialty fibers becoming more sustainable?

A: Through biotech-made biodegradable fibers, upcycled materials like citrus peel textiles, agricultural or seaweed-based biomaterials, and closed-loop manufacturing with supply chain transparency.

Q5: Why is market value expected to decline slightly despite rising demand?

A: While specialized applications grow, cost pressures and more efficient production methods may shrink overall market value, resulting in a slight dip projected at –0.8% CAGR from 2025–2033.

Q6: Are smart textiles being dominated by specialty fibers?

A: Absolutely. E-textiles embed conductive or sensor fibers directly into fabrics, enabling wearable electronics, responsive clothing, and health-monitoring textiles.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0