Upgrade Your Truck’s Power With Cummins Conversion Parts

Swapping in a Cummins diesel isn’t just about bragging rights. With the right Cummins conversion parts, you can transform your truck into a powerhouse of strength, fuel economy, and reliability.

For truck enthusiasts and heavy-duty haulers, performance isn't just a preference it's a necessity. Whether you're towing a fifth wheel, navigating off-road terrain, or simply chasing that perfect balance between horsepower and reliability, Cummins diesel engines are often at the top of the upgrade list. But transforming a gas or another diesel engine setup into a Cummins-powered machine isn't a one-step process. It requires precision, planning, and most importantly, Cummins conversion parts.

Cummins engine swaps have gained momentum over the years for their proven durability, exceptional torque output, and compatibility with a wide range of vehicles. However, even the most powerful engine won’t perform well without the right supporting components. That’s where premium-quality conversion parts come in.

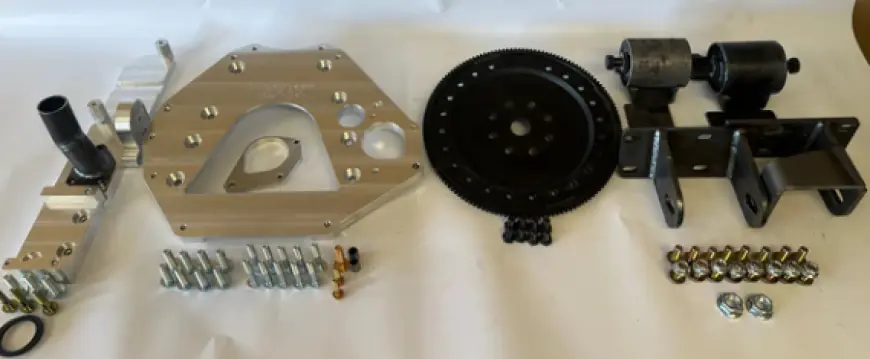

Essential Parts You’ll Need for a Smooth Cummins Swap

A Cummins swap isn't plug-and-play. Each vehicle requires a unique approach depending on the original drivetrain. Here are the most critical parts you’ll need to plan for:

1. Adapter Plates and Transmission Kits

To connect a Cummins engine to a different make's transmission—like a Ford or GM—you’ll need a transmission adapter plate. These plates ensure precise alignment between engine and transmission while preserving proper torque converter engagement.

2. Motor Mounts and Brackets

Factory motor mounts are often incompatible with the Cummins block. Custom mounts or adjustable brackets are necessary to securely fit the new engine into your chassis without misalignment or stress.

3. Cooling System Upgrades

Diesel engines like Cummins produce more heat. Upgrading to a larger radiator, intercooler, and ensuring your coolant hoses match the new setup is vital for long-term performance.

4. Wiring Harness and ECM Integration

Perhaps the most complex part of the process, integrating your Cummins ECM with the existing vehicle electronics requires a quality standalone harness or a skilled technician. This step ensures proper engine management, diagnostics, and even dash gauge function.

5. Fuel System Adjustments

Gas-powered trucks need a completely new diesel fuel system. That includes upgraded fuel lines, filters, tanks, and a lift pump to feed the Cummins at the correct pressure.

Situations That Demand a Cummins Swap

While many enthusiasts upgrade just for performance, there are plenty of practical reasons to consider Cummins conversion parts:

-

Blown or aging gas engine in a work truck

-

Lack of towing capability in your current setup

-

Frequent overheating or transmission strain

-

Need for better fuel economy in commercial vehicles

-

Desire for longer engine lifespan in off-grid builds

These aren't just convenience upgrades—they're often financially smarter long-term choices.

Cost vs Value: Is It Worth It?

A Cummins conversion can range from $8,000 to over $25,000 depending on parts, labor, and the vehicle platform. While this may seem high upfront, many find it's an investment in reliability and performance. Cummins engines can last upwards of 400,000 miles with proper maintenance, while also increasing resale value for the right buyer.

Key Value Points:

-

Increased torque for towing

-

Better fuel efficiency (especially compared to V8 gas engines)

-

Easier access to replacement parts

-

Proven longevity and fewer breakdowns

Tips for a Successful Cummins Conversion

-

Plan everything before buying parts. Not every Cummins variant fits all trucks—know your goals.

-

Source parts from reputable manufacturers. Cheap conversion parts often lead to alignment issues or even drivetrain damage.

-

Look for complete kits. Buying an all-in-one conversion kit ensures compatibility and can reduce labor time.

-

Consult forums and experts. Platforms like CumminsForum or diesel swap groups offer real-world advice and install guides.

-

Don’t skimp on tuning. After the physical conversion, proper ECM tuning and diagnostics ensure optimal performance.

Common Mistakes to Avoid

-

Underestimating the wiring job

Many swaps stall out when it’s time to connect the electronic systems. This isn’t just about starting the engine—it’s about getting it to run right and work with your dashboard. -

Ignoring the transmission match-up

Just because it fits doesn’t mean it’s built to handle the torque of a Cummins. If you’re keeping the stock transmission, verify its torque rating. -

Skipping drivetrain upgrades

More torque often demands stronger driveshafts, differentials, and even axle upgrades.

Final Thoughts

Swapping in a Cummins diesel isn’t just about bragging rights. With the right Cummins conversion parts, you can transform your truck into a powerhouse of strength, fuel economy, and reliability. Whether you’re a weekend warrior, a heavy hauler, or someone building the ultimate bug-out rig, a Cummins swap—when done right—is one of the best upgrades you can make.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0