The Rise of Manganese Plate Technologies

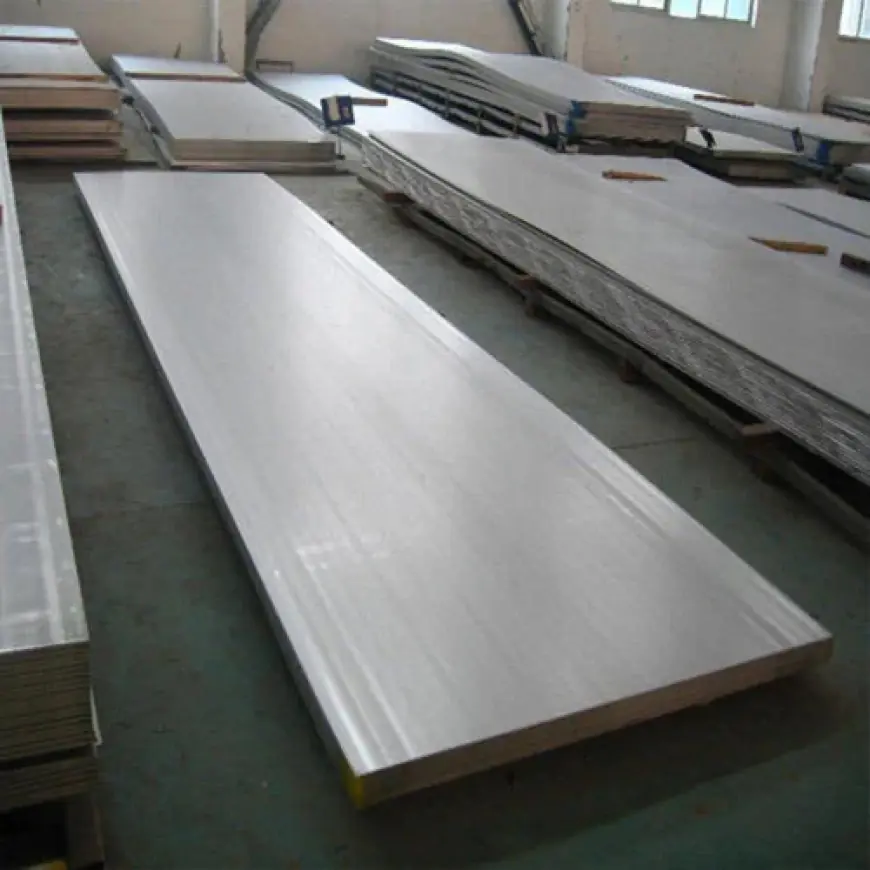

Industrial engineering is currently undergoing profound change, propelled by manganese plate that redefine what modern manufacturing can accomplish. These advanced composite plates mark a decisive advance in material science, delivering capabilities that shift the frontier of technological feasibility.

Foundational Metallurgical Advancements

Manganese plates are characterized by a distinctive interplay of microstructural attributes that confer frame rigidity, endurance, and exceptional resilience against both corrosive and mechanical stressors.

This intrinsic architecture outperforms standard metallic candidates, prompting engineers to incorporate the material into mission-critical applications that compel the highest level of mechanical and environmental performance.

Extended Performance Envelope

The operational advantages of manganese plate exceed the benchmarks set by legacy materials. These components exhibit superior abrasion resistance coupled with stable dimensionality, even when subjected to peak load cycles. The capacity to retain mechanical integrity in the harshest operational regimes positions manganese plates as a pivotal resource in sectors demanding unyielding performance durability.

Controlled Precision Fabrication

The realization of premium manganese plates hinges upon advanced metallurgical control and tight engineering tolerances. The fabrication sequence demands rigorous manipulation of thermal profiles, applied pressures, and elemental concentrations. Ongoing refinements in processing conditions are continuously pursued by metallurgical experts to perfect microstructural attributes, thereby advancing the material’s performance envelope and accelerating the trajectory of engineering innovation.

Versatile Industrial Applications

Manganese plates emerge as indispensable assets across the spectrum of industrial activity, seamlessly bridging assignments from heavy earthmoving equipment to bespoke instrumentation. Their superior toughness and immunity to corrosive and abrasive environments confer sustained operational continuity, drastically reducing the frequency and cost of component replacement.

This inherent durability invites a widening array of applications, while continual refinements in processing and alloying amplify their design flexibility.

Future Technological Horizons

Cutting-edge inquiry into manganese alloy systems foreshadows enhancements that may reconfigure prevailing paradigms of material utility. Next-generation microstructural optimization, in conjunction with additive processing methodologies, holds the promise of discovering tailored gradients of hardness and toughness.

Such refinements further entrench manganese plate as platforms upon which future machinery, robotics, and structural assemblages may be conceived with both weight savings and durability dictated by their progressive mechanical performance.

Collectively, manganese plates constitute both a crowning material-science laureate and a strategic enabler of future industrial success, blending robust performance with a trajectory of perpetual enhancement across the domains of design and engineering.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0