Stainless Steel 904L Pipes: The Ultimate Choice for Corrosion-Resistant Systems

Discover the benefits, applications, and advantages of Stainless Steel 904L pipes. Ideal for chemical, marine, and high-pressure systems requiring corrosion resistance

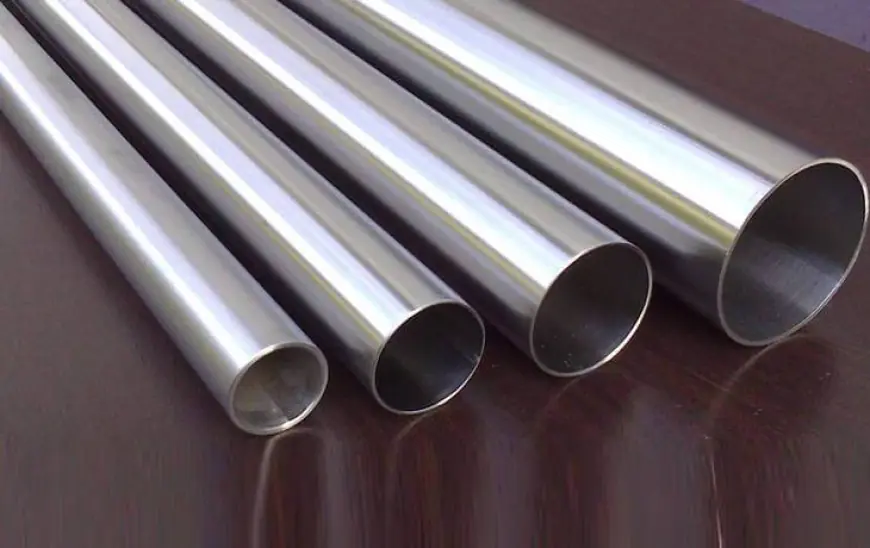

In industries where extreme environments and corrosive substances are common, material choice can make or break operations. Stainless Steel 904L pipes have emerged as a superior solution, combining high corrosion resistance, mechanical strength, and versatility. These pipes are widely used in chemical processing, marine applications, pharmaceuticals, and oil and gas industries. Their robust properties ensure reliable performance even under harsh conditions.

Understanding Stainless Steel 904L Pipes

904L stainless steel pipes belong to the austenitic family of stainless steel. They are engineered with high levels of chromium, nickel, and molybdenum, with added copper. This combination provides excellent resistance against strong oxidizing acids, including sulfuric and phosphoric acids.

The low carbon content in 904L stainless steel prevents sensitization during welding, reducing the risk of intergranular corrosion. This makes the pipes ideal for critical industrial applications where reliability and safety are paramount.

Features of Stainless Steel 904L Pipes

-

High Corrosion Resistance:

904L pipes withstand pitting and crevice corrosion in chloride-rich and acidic environments, making them perfect for marine and chemical applications. -

Superior Mechanical Strength:

These pipes maintain excellent tensile and yield strength under high-pressure conditions, ensuring structural stability. -

Resistance to Extreme Temperatures:

They perform well across a wide temperature range, from sub-zero conditions to high-heat industrial processes. -

Weldability and Fabrication:

The low carbon content allows easy welding and forming without compromising corrosion resistance. -

Durable and Long-Lasting:

904L stainless steel pipes offer excellent toughness, fatigue resistance, and durability in aggressive environments.

Industrial Applications of 904L Stainless Steel Pipes

1. Chemical Processing:

904L pipes are highly resistant to strong acids and chemicals, making them ideal for transporting corrosive fluids in chemical and petrochemical plants.

2. Marine and Offshore Applications:

Exposure to seawater and salt spray can corrode standard stainless steel. 904L pipes resist corrosion in these conditions, making them suitable for desalination plants, offshore rigs, and shipbuilding.

3. Pharmaceutical Industry:

Hygiene and chemical resistance are critical in pharmaceuticals. 904L pipes resist contamination and maintain structural integrity in clean-room environments.

4. Food and Beverage Industry:

These pipes handle acidic and alkaline fluids efficiently, ensuring product safety in beverage processing, dairy production, and food manufacturing.

5. Oil and Gas Industry:

904L stainless steel pipes transport highly corrosive crude oil and chemicals, offering durability in refineries and offshore pipelines.

Benefits of Choosing Stainless Steel 904L Pipes

-

Extended Lifespan:

High corrosion resistance ensures long-term use with minimal maintenance. -

Operational Safety:

Resistance to stress corrosion cracking and pitting ensures safer operations in high-risk environments. -

Cost Efficiency:

Though the initial cost may be higher than other stainless steel grades, reduced maintenance and replacement costs make 904L pipes economically beneficial. -

Versatile Fabrication:

Easy welding, bending, and forming allow custom piping layouts without compromising performance. -

Eco-Friendly:

Long-lasting 904L stainless steel pipes reduce waste and replacement needs, contributing to sustainable industrial practices.

Comparison with Other Stainless Steel Grades

While 304 and 316 stainless steel pipes are commonly used, 904L pipes offer superior performance in corrosive environments. Compared to 316 stainless steel, 904L withstands higher concentrations of acids and chloride solutions, making it the preferred choice for marine and chemical industries.

Tips for Maintaining 904L Stainless Steel Pipes

Even though 904L stainless steel pipes are highly durable, proper maintenance ensures maximum lifespan:

-

Clean regularly with mild detergents to remove surface deposits.

-

Avoid exposure to harsh chemicals that can damage the oxide layer.

-

Conduct routine inspections for signs of wear, pitting, or mechanical damage.

-

Store in dry, ventilated areas to prevent surface staining and corrosion.

Conclusion

Stainless Steel 904L pipes deliver unmatched corrosion resistance, strength, and versatility. From chemical plants to marine structures, these pipes perform reliably in the harshest conditions. Their high durability, excellent weldability, and long lifespan make them a smart investment for industries where safety and performance are critical.

Choosing 904L stainless steel pipes ensures reduced maintenance, operational safety, and cost efficiency over time. For any high-pressure, high-corrosion application, 904L pipes stand out as the ultimate solution, combining superior mechanical properties with exceptional resistance to aggressive chemicals.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0