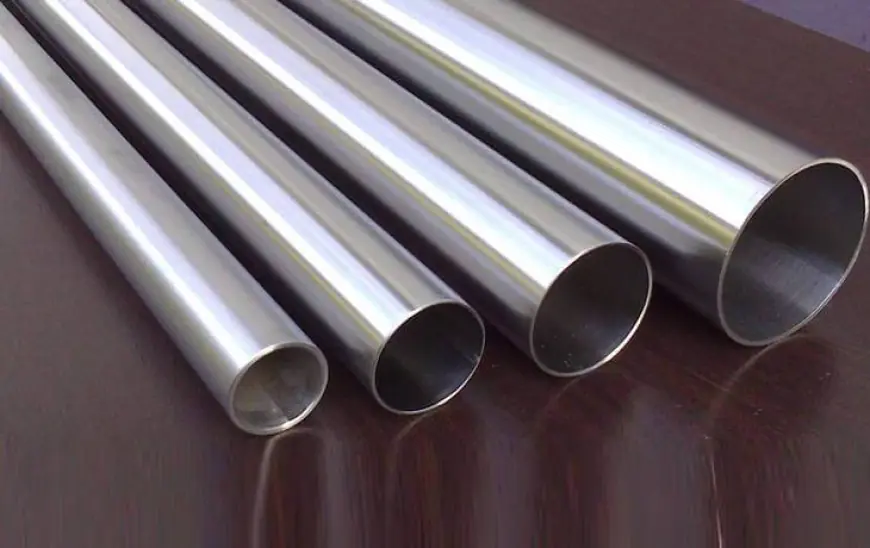

SS 304L Seamless Pipes & Tubes: Properties, Applications, and Benefits

Stainless steel has become one of the most trusted materials in modern industries, known for its durability, corrosion resistance, and versatility. Among its many grades, SS 304L seamless pipes and tubes hold a prominent position due to their excellent balance of strength, workability, and resistance to different environments. From chemical plants to food processing units, these seamless products are widely used in demanding applications.

This blog takes you through the essential properties, benefits, and applications of SS 304L seamless pipes and tubes, helping you understand why they are the go-to choice for several industries.

What is SS 304L Stainless Steel?

SS 304L is a low-carbon version of SS 304, belonging to the austenitic stainless steel family. The "L" in 304L stands for "low carbon," which enhances its weldability and reduces the risk of carbide precipitation during welding. This makes SS 304L highly suitable for industries where welding and fabrication are critical.

Key Composition of SS 304L Stainless Steel:

-

Chromium: 18–20%

-

Nickel: 8–12%

-

Low Carbon: ≤ 0.03%

This composition allows SS 304L to resist oxidation, scaling, and corrosion in a variety of environments.

Properties of SS 304L Seamless Pipes & Tubes

SS 304L seamless pipes and tubes are known for their distinctive properties, making them reliable across different industrial applications.

-

Corrosion Resistance: Superior resistance to atmospheric and chemical corrosion.

-

High Strength: Adequate tensile and yield strength for pressure and structural uses.

-

Weldability: Low carbon content ensures excellent weldability without post-weld annealing.

-

Temperature Tolerance: Performs well at both cryogenic and elevated temperatures.

-

Hygienic Surface: Smooth surface finish makes it suitable for sanitary applications.

Advantages of Using SS 304L Seamless Pipes & Tubes

When you talk about stainless steel in piping systems, seamless pipes and tubes in grade 304L stand out for several reasons:

-

Leak-Free Performance

Being seamless, these pipes and tubes eliminate the risk of leaks or weak spots, ensuring long-term reliability. -

Extended Durability

Their resistance to rust, scaling, and chemical attacks enhances longevity, reducing replacement costs. -

Easy Fabrication

SS 304L can be easily machined, cut, and welded, offering flexibility in design and installation. -

Low Maintenance

The self-healing chromium oxide layer reduces the need for frequent maintenance. -

Cost-Effective

A balance between affordability and performance makes them a cost-effective choice compared to other stainless steel grades.

Applications of SS 304L Seamless Pipes & Tubes

SS 304L seamless pipes and tubes are used in a wide range of industries. Their versatility makes them suitable for both structural and process applications.

1. Chemical and Petrochemical Industry

-

Used for handling corrosive chemicals and fluids.

-

Ideal for pipelines, heat exchangers, and condensers.

2. Food and Beverage Industry

-

Perfect for hygienic processing systems.

-

Used in dairy, brewery, and beverage production equipment.

3. Pharmaceutical Industry

-

Ensures sterility and prevents contamination.

-

Commonly used in medical equipment and clean room piping.

4. Oil and Gas Sector

-

Suitable for offshore and onshore pipelines.

-

Resists harsh environmental conditions.

5. Construction and Architecture

-

Applied in structural frameworks, railings, and support systems.

-

Enhances aesthetics while providing strength.

6. Water Treatment and Desalination Plants

-

Ideal for transporting purified and saline water.

-

Withstands chloride-rich environments.

7. Power Plants and Energy Sector

-

Used in boilers, heat exchangers, and high-pressure piping.

-

Provides durability in extreme temperature environments.

Why Choose SS 304L Seamless Pipes & Tubes Over Other Grades?

When comparing SS 304L seamless pipes with other stainless steel grades, the standout feature is its low carbon content. Unlike standard 304, SS 304L minimizes the risk of intergranular corrosion after welding, making it more reliable for welded structures. It also balances cost and performance better than premium alloys like 316L, making it widely popular in cost-sensitive projects.

Manufacturing Process of SS 304L Seamless Pipes & Tubes

The production of seamless pipes and tubes involves a series of steps to ensure strength and durability:

-

Selection of Raw Material – High-quality SS 304L billets are chosen.

-

Piercing and Extrusion – The billets are pierced and hot-extruded into hollow tubes.

-

Sizing and Elongation – The tubes are elongated and sized to meet specific dimensions.

-

Heat Treatment – Annealing ensures strength and stress relief.

-

Surface Finishing – Pickling and polishing enhance appearance and corrosion resistance.

-

Testing and Inspection – Non-destructive tests confirm quality and safety compliance.

Standards and Specifications

SS 304L seamless pipes and tubes are manufactured in compliance with international standards. Some of the common standards include:

-

ASTM A312 / A213 – Seamless stainless steel pipes and tubes.

-

ASME SA312 / SA213 – Boiler, heat exchanger, and pressure piping.

-

DIN, EN, JIS – International equivalents for varied applications.

Maintenance Tips for Long Life

While SS 304L seamless pipes and tubes are low maintenance, a few practices can extend their service life:

-

Clean regularly to prevent surface deposits.

-

Avoid exposure to chlorides beyond recommended limits.

-

Inspect welds and joints periodically.

-

Use proper protective coatings in extreme environments.

Conclusion

SS 304L seamless pipes and tubes are the backbone of numerous industries due to their strength, corrosion resistance, and adaptability. They combine durability with affordability, making them the preferred choice for industries ranging from food processing to oil and gas. Whether for structural support or process pipelines, SS 304L continues to deliver unmatched performance.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0