Encorafenib Production Process with Cost Analysis

The Encorafenib Production Process with Cost Analysis report delves into the intricate details of manufacturing Encorafenib, a critical drug used in cancer therapy.

Introduction

The Encorafenib Production Process with Cost Analysis report delves into the intricate details of manufacturing Encorafenib, a critical drug used in cancer therapy. This comprehensive analysis covers the production process, resource procurement, market dynamics, raw material requirements, and cost factors. By understanding these aspects, businesses can optimize production efficiency, reduce costs, and make informed strategic decisions.

Request for Free Sample: https://www.procurementresource.com/production-cost-report-store/encorafenib/request-sample

Procurement Resource Assessment for Encorafenib Production

Overview

Procurement resource assessment is a vital aspect of the Encorafenib production process. It involves evaluating the availability, cost, and quality of raw materials and resources required for the manufacturing of Encorafenib. This assessment ensures a steady supply of high-quality materials, minimizes production disruptions, and optimizes costs.

Key Resources

-

Raw Materials: Encorafenib production requires specific chemical precursors and intermediates. Identifying reliable suppliers and securing contracts for these materials are crucial steps.

-

Manufacturing Equipment: High-precision equipment is essential for the synthesis and formulation of Encorafenib. Assessing the performance and maintenance of these machines impacts production efficiency.

-

Labor Force: Skilled personnel are needed to operate equipment, monitor processes, and ensure quality control. Proper training and staffing are essential for maintaining production standards.

Understanding Encorafenib

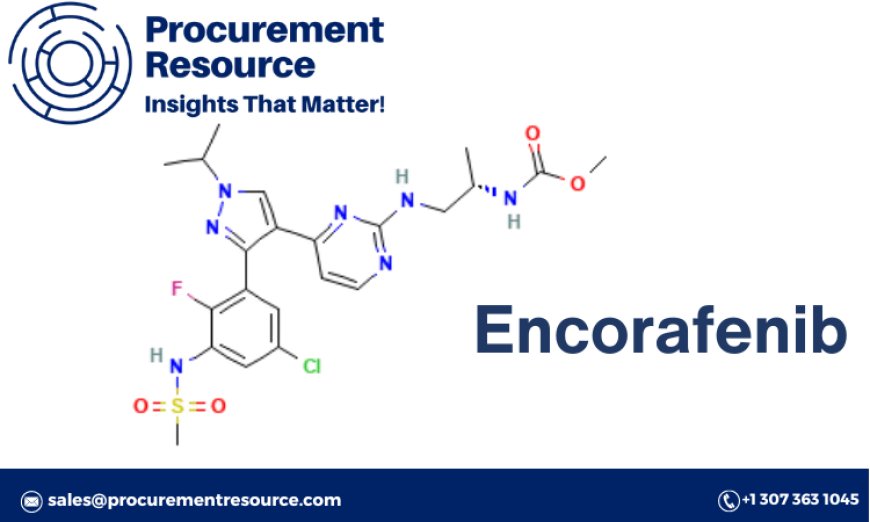

What is Encorafenib?

Encorafenib is a targeted therapy used to treat certain types of cancer, including melanoma. It works by inhibiting the activity of specific proteins that contribute to cancer cell growth. As a selective BRAF inhibitor, Encorafenib is critical in personalized cancer treatment regimens.

Production Process

The production of Encorafenib involves several key steps:

-

Synthesis: The chemical synthesis of Encorafenib begins with the preparation of starting materials and intermediates. This phase includes several reaction steps to form the active pharmaceutical ingredient (API).

-

Purification: Post-synthesis, the API undergoes purification to remove impurities and ensure the drug's efficacy and safety.

-

Formulation: The purified API is then formulated into the final drug product, which includes the addition of excipients and the preparation of dosage forms such as tablets or capsules.

-

Quality Control: Rigorous quality control tests are conducted to ensure the drug meets all regulatory standards and specifications.

Market Drivers for Encorafenib

Key Factors Influencing the Market

-

Cancer Incidence: The rising incidence of cancer globally drives demand for targeted therapies like Encorafenib. Increased cancer awareness and early diagnosis contribute to higher treatment needs.

-

Regulatory Approvals: New approvals and indications for Encorafenib by regulatory agencies expand its market potential. Ongoing research and clinical trials also influence market dynamics.

-

Competitive Landscape: The presence of alternative treatments and competitive drugs affects Encorafenib’s market position. Continuous innovation and development are crucial to maintaining a competitive edge.

-

Pricing and Reimbursement: Pricing strategies and reimbursement policies impact the accessibility and affordability of Encorafenib. Market access strategies play a significant role in its commercial success.

Raw Materials Requirements for Encorafenib Production

Key Raw Materials

-

Chemical Precursors: High-purity chemical precursors are essential for the synthesis of Encorafenib. These include specific reagents and solvents used in the chemical reactions.

-

Intermediates: Intermediate compounds are required during the synthesis phase. Proper handling and storage of these materials are critical for maintaining quality.

-

Excipients: In the formulation stage, excipients such as fillers, binders, and stabilizers are used. These components ensure the stability and efficacy of the final drug product.

Sourcing and Supply Chain

Establishing reliable sources for raw materials and intermediates is crucial. Long-term agreements with suppliers and strategic sourcing can mitigate risks related to supply disruptions and price volatility.

Costs and Key Process Information

Cost Analysis

-

Production Costs: The production cost of Encorafenib includes expenses related to raw materials, labor, equipment, and facility maintenance. Efficient management of these costs is essential for maintaining profitability.

-

Regulatory Compliance: Compliance with regulatory requirements involves additional costs related to testing, certification, and documentation. Ensuring adherence to these standards is crucial for market approval.

-

Quality Assurance: Investing in quality control and assurance processes ensures the final product meets all safety and efficacy standards. This includes costs associated with testing and validation.

Key Process Information

-

Process Optimization: Continuous process optimization and improvements can lead to cost savings and increased production efficiency. Implementing best practices and technological advancements are beneficial.

-

Production Capacity: Scaling production capacity to meet market demand while controlling costs is a critical aspect of the production process. Strategic planning and investment in scalable technologies are key.

Looking for an Exhaustive and Personalized Report

For businesses seeking an in-depth and tailored analysis of the Encorafenib production process, including cost considerations and optimization strategies, a personalized report can provide significant insights. Such a report will help substantiate business decisions and enhance production efficiency.

About Us:

Procurement Resource is an invaluable partner for businesses seeking comprehensive market research and strategic insights across a spectrum of industries. With a repository of over 500 chemicals, commodities, and utilities, updated regularly, they offer a cost-effective solution for diverse procurement needs. Their team of seasoned analysts conducts thorough research, delivering clients with up-to-date market reports, cost models, price analysis, and category insights.

By tracking prices and production costs across various goods and commodities, Procurement Resource ensures clients receive the latest and most reliable data. Collaborating with procurement teams across industries, they provide real-time facts and pioneering practices to streamline procurement processes and enable informed decision-making. Procurement Resource empowers clients to navigate complex supply chains, understand industry trends, and develop strategies for sustainable growth.

Contact Us:

Company Name: Procurement Resource

Contact Person: Benking sley

Email: sales@procurementresource.com

Toll Free Number: USA & Canada - Phone no: +1 307 363 1045 | UK - Phone no: +44 7537 132103 | Asia-Pacific (APAC) - Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA