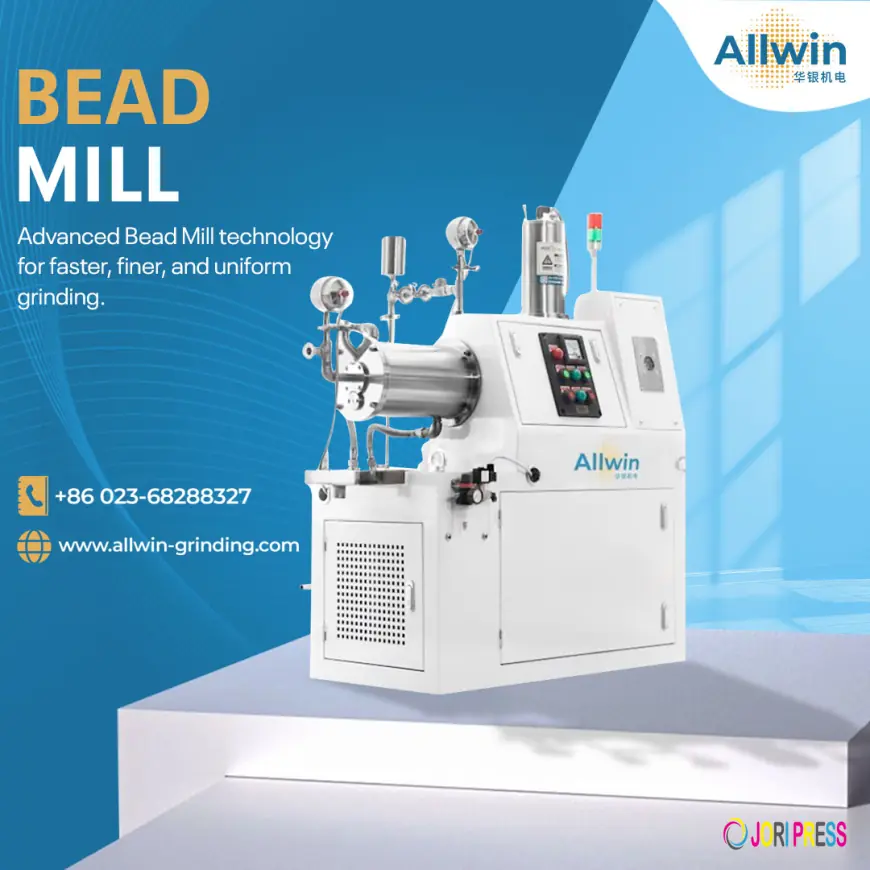

Choose Allwin’s Bead Mills For Fast Production And Improved Consistency

The Bead mill has been officially recognized as the preferred option for grinding and dispersing liquids. The best manufacturers of bead mill ensure they are affordable, with explosion-proof, energy-saving features that make them an option for long-term use in the industrial sector.

In manufacturing across multiple industries, fine particle grinding is vital. One such machine that operates on this principle is a bead mill. This device is a high-performance machine that works continuously to deliver a uniform particle size, where achieving the particle size is vital. This includes the pharmaceuticals, pesticides, coatings, food, chemicals, and many other industries. In all these applications, this machine processes the good material by grinding and mixing the materials, typically in liquids or slurries.

However, each sector, based on its products, required different customization to ensure its mixtures turned out fine. In this comprehensive blog, we will explore the bead mill and its different types. Additionally, the manufacturers that provide the best machine with customization to match the needs. And now, which sectors do they serve, and for what work?

What is a Bead Mill & Its Components?

A Bead Mill is a type of high-performance machine that is used for grinding and dispersing materials. It is designed in a way to reduce the particle size and enhance the material dispersion. This bead mill machine uses tiny round beads (generally made up of zirconia, glass, or steel) to move through the materials. As these beads move, they create friction, which helps them break down the large particles into smaller ones. They are highly preferred over traditional milling methods because they have increased the efficiency in the production process. Now, let’s see what parts of the bead mill.

This has several parts, each serving an important function. The wet bead mill runs continuously, with the materials always grinding or being mixed.

-

Grinding Chamber: This is the part where the first step begins. In this, materials and beads are placed to start.

-

Rotator or Agitator: Then, in the second step, the agitator moves the beads through the material, ensuring grinding and dispersion.

-

Beads: These are the grinding media, which hit the large material and break it down into small particles.

-

Feeding Pump: This continuously supplies the material into the grinding chamber without delay.

-

Discharge Systems: Lastly, the machine's discharge system removes the finished slurry after grinding.

-

Cooling Systems: Some industrial nano bead mill for nano-particle dispersion use a cooling system at the end to manage heat generation during the process.

Which Principle Does The Bead Mill Follow To Operate?

The working principle of the bead mill machine is based on four things: shear, force, impact, and attrition. Here’s a step breakdown for how it operates.

1. Feeding the Materials

This process starts off as a liquid slurry, or a mixture of solids and liquids, which is introduced into the wet bead mill. This mixture is generally pre-mixed for uniformity. Only then is it pumped into the grinding chamber.

2. Agitation of Beads

Inside the grinding chamber, the rotatory disc or agitator rotates vigorously to create a high-energy motion among the beads. This motion causes beads to collide and generate friction, which helps reduce particle size.

3. Shear and Impact Force

The intense collision between the moving beads and particles leads to the generation of shear and impact forces, effectively resulting in particle size reduction. These energy and impact forces can be adjusted by optimizing factors such as bead size, rotor speed, and rotor type.

4. Separation & Output

After the grinding process, the final step of separating the output is performed. The discharged product, which is finely ground material, is separated from the beads using a separator or a screen. However, the nano wet bead mill keeps the beads in the mill for the next cycle.

Different Types Of Bead Mills for Different Applications

There are multiple types of high-precision nano bead mill for ultra-fine grinding applications. Different types serve different purposes for different industries. That's precisely why, based on the requirements, here are a few top ones.

|

Type |

Scale |

Power |

Applications |

Key Features |

|

HZ Plus Super‑Fine Nano Bead Mill |

Medium to large scale |

High‑power motor, nano‑level fineness |

Batteries, ceramics, coatings, inks |

Advanced grinding system, nano dispersion, customizable chamber materials |

|

FS Cone Barrel Nano Pin Bead Mill |

Flexible capacity |

Precision pin design for high efficiency |

Pharmaceuticals, cosmetics, chemicals |

Cone barrel design, uniform particle size, energy‑saving |

|

SP Horizontal Disk Bead Mill |

Mid‑scale |

Stable horizontal disk system |

Paints, inks, paper |

Easy maintenance, consistent throughput, robust design |

|

AP Horizontal Disk Bead Mill |

Industrial scale |

High‑power horizontal disk |

Coatings, ceramics, food |

Optimized for continuous production, durable components |

|

SH Submicron Pin Bead Mill |

Small to mid‑scale |

Submicron grinding capability |

Electronics (MLCC/LTCC), fine chemicals |

Pin structure for ultra‑fine dispersion, precision control |

Various Models of HZ Plus Series Nano-Bead Mill

The HZ Plus series offers four models for varying production scales. These models depict an energy-efficient nano bead mill for chemical processing.

The HZ Plus 30 features a 30-liter chamber with 30 kW of motor power, delivering throughput capacities of 110-1100 Kg/h using grinding media ranging from 0.1 to 2.0 mm in diameter. Its compact size makes it ideal for mid-scale production environments.

The HZ Plus 50 steps up with a 50-liter net chamber volume and 37 KW motor, achieving throughput rates of 165 to 1430 Kg/h. This model balances power and efficiency, making it well-suited for coatings and inks applications with the same 0.1 – 2.0 mm grinding media diameter range.

For higher-capacity needs, the HZ Plus 100 provides a 100-liter chamber powered by 55 to 75 KW motors, supporting throughput capacities from 330 to 3630 Kg/h. This model is specifically suited for battery materials processing while maintaining the standard grinding media diameter specifications.

At the industrial scale, the HZ Plus 250 offers a 250-liter chamber with a 75-90 kW motor, capable of processing 550-5000 Kg/h. Optimized for continuous grinding operations, this flagship model delivers maximum productivity for large-scale manufacturing requirements.

Advantages of Using A Robust Bead Mill In Your Production

A well-built nano bead mill machine is designed for precision, reducing particle size from 300 microns to the 100-nanometer range. When selecting the right bead mill, numerous considerations need to be made for a nano bead mill machine for high-viscosity materials. To have the best of advantages, like:

1. High Efficiency

The process of large volumes of material can be rapid if the bead mill manufacturer has built them with advanced technology and the best materials. It can improve production by up to 10 times, making it a high-value, high-performing production.

2. Even Particle Size

The bead mills can refine the particles to an even and small size. This is important for the pharmaceutical and cosmetic industries.

3. Versatility

The bead mill can handle a wide range of materials, from thin liquids to thick pastes, in no time, and achieve uniform grinding. This makes them the best nano bead mill for pharmaceutical and cosmetic formulations. Additionally, for the food, paint coating, etc.

4. Energy Efficient

Bead mills use less energy than other grinding machines, for example, ball mills.

Final Thoughts!

The Bead mill has been officially recognized as the preferred option for grinding and dispersing liquids. The best manufacturers of bead mill ensure they are affordable, with explosion-proof, energy-saving features that make them an option for long-term use in the industrial sector. One such bead mill manufacturer is Allwin. They have been in the market since 1993, making the best bead mills in the world, and they serve almost all industries with their products. They also specifically customized the bead mills to meet industry needs and all the details of the type.

The model and the required time to build your prototype are available on the website. You can visit today and explore, and you can also connect with their support team for further details.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0