Why Aluminum Extrusion Is the Best Choice for Lightweight and Durable Structures

In the construction industry, aluminum extrusion is widely utilized for creating windows, doors, curtain walls, and modular building components.

Aluminum extrusion offers an unparalleled combination of strength, flexibility, and lightweight properties, making it an excellent choice for structural applications. Unlike traditional materials such as steel or wood, aluminum extrusion is highly resistant to corrosion, ensuring longevity in both indoor and outdoor environments. Its inherent resistance to rust and other forms of degradation significantly reduces maintenance costs, making it an attractive option for architects and engineers looking for long-lasting structural solutions.

Another major advantage of aluminum extrusion is its superior strength-to-weight ratio. Despite being lightweight, aluminum extrusions can bear substantial loads, making them ideal for structural applications in industries such as construction, automotive, aerospace, and manufacturing. This feature allows for the creation of complex yet durable structures without compromising on weight, reducing transportation and installation costs significantly.

How Aluminum Extrusion Enhances Design Versatility

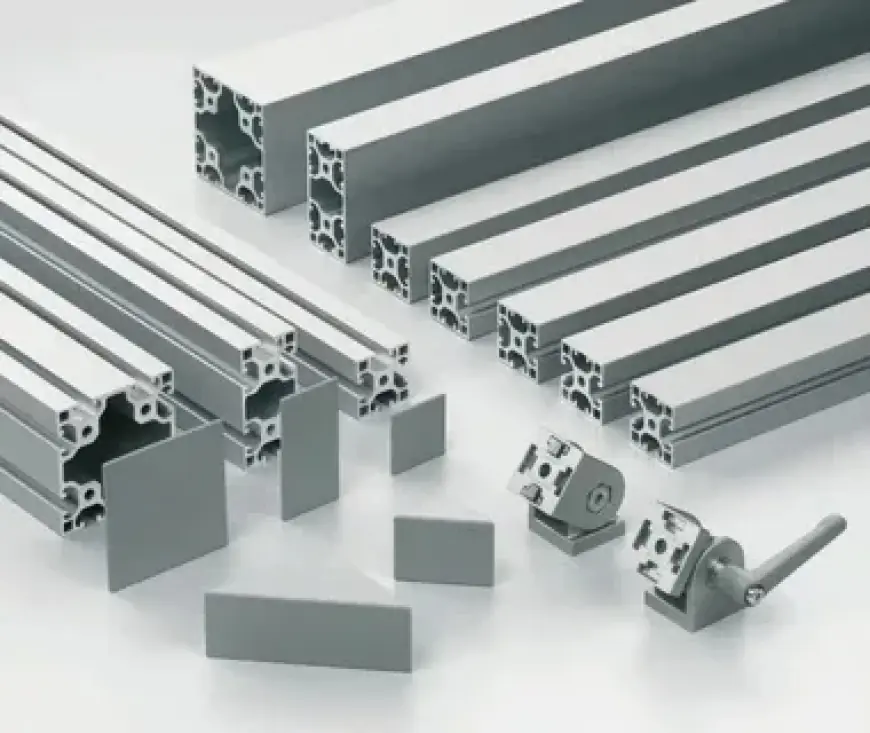

One of the most compelling reasons why aluminum extrusion is preferred in various industries is its exceptional design versatility. The extrusion process allows aluminum to be shaped into a wide variety of complex profiles, meeting specific project requirements. Whether designing intricate architectural facades or highly specialized industrial components, aluminum extrusion provides unparalleled flexibility compared to traditional manufacturing methods.

Additionally, aluminum extrusion enables engineers and designers to integrate multiple functions into a single profile. Features such as channels, ridges, and hollow sections can be incorporated into the design, reducing the need for additional assembly processes. This not only enhances the aesthetic appeal of the final product but also simplifies manufacturing, leading to faster production times and reduced costs.

The Role of Aluminum Extrusion in Lightweight Construction

Aluminum extrusion plays a vital role in the development of lightweight construction materials. Due to its reduced density compared to steel, aluminum extrusions significantly contribute to weight reduction in structures without compromising strength. This is particularly beneficial in applications such as high-rise buildings, bridges, and modular structures, where minimizing weight can enhance overall stability and efficiency.

Moreover, lightweight aluminum extrusions facilitate ease of installation and transportation. Their reduced weight allows for faster assembly, requiring fewer workers and equipment on-site. This results in significant cost savings for construction projects, making aluminum extrusion a highly practical and economical choice for lightweight structures.

Durability and Sustainability of Aluminum Extrusions

Aluminum extrusion is not only strong and lightweight but also incredibly durable. It exhibits excellent resistance to extreme weather conditions, UV radiation, and chemical exposure, making it suitable for both indoor and outdoor applications. Unlike materials such as wood, which can warp or degrade over time, aluminum retains its structural integrity for decades, ensuring long-term reliability in various industries.

Furthermore, aluminum is a sustainable and environmentally friendly material. It is 100% recyclable without losing its original properties, allowing for repeated use in different applications. The recycling process requires only a fraction of the energy needed for primary aluminum production, significantly reducing the carbon footprint. This makes aluminum extrusion an eco-conscious choice for companies looking to enhance sustainability efforts in their structural designs.

Applications of Aluminum Extrusion in Various Industries

The use of aluminum extrusion extends across multiple industries due to its numerous advantages. In the automotive sector, for instance, aluminum extrusions are used to create lightweight vehicle frames and components, improving fuel efficiency and reducing emissions. Similarly, in the aerospace industry, extruded aluminum parts contribute to the development of lightweight yet durable aircraft structures, optimizing performance and safety.

In the construction industry, aluminum extrusion is widely utilized for creating windows, doors, curtain walls, and modular building components. Its strength, corrosion resistance, and ease of customization make it the go-to material for modern architectural designs. Additionally, industries such as electronics, transportation, and renewable energy benefit from aluminum extrusion’s superior heat dissipation and adaptability, further proving its versatility in structural applications.

In conclusion, aluminum extrusion stands out as the best choice for lightweight and durable structures due to its unmatched strength-to-weight ratio, design flexibility, durability, and sustainability. As industries continue to seek innovative and efficient solutions, aluminum extrusion remains a vital material for developing high-performance structural applications that meet the demands of the modern world.