The Rise of Photocatalytic Coating: A Greener Way to Purify Indoor and Outdoor Environments

Self-cleaning coatings are surface treatments that rely on the process of photocatalysis to break down organic and inorganic pollutants upon exposure to sunlight or artificial UV light.

What are Self-cleaning coatings?

Self-cleaning coatings are surface treatments that rely on the process of photocatalysis to break down organic and inorganic pollutants upon exposure to sunlight or artificial UV light. These coatings are applied as very thin films, typically made of titanium dioxide (TiO2) which acts as the photocatalyst. When TiO2 absorbs UV rays, it generates reactive oxygen species that can oxidize pollutants like volatile organic compounds (VOCs), bacteria, mold, and other organic matter. Over time, this leads to the cleansing or self-cleaning of the coated surface.

How do they Work?

On a basic level, photocatalytic oxidation involves four main steps when a surface is coated with TiO2 and exposed to light:

1) UV light excites the TiO2 catalyst, generating positively charged holes and negatively charged electrons.

2) The electrons and holes initiate redox reactions on the surface that produce reactive oxidative species like superoxide radicals, hydroxide radicals and hydrogen peroxide.

3) These strong oxidizing agents then react with and break down organic pollutants that come into contact with the surface.

4) The end products are inert and no longer pose health risks - being mostly carbon dioxide, water and mineral acids. This cleansing goes on as long as the photocatalytic surface is exposed to light.

Applications in Buildings and Construction

Photocatalytic Coating are increasingly being applied to building exteriors, interior spaces, windows, rooftops and pavers to purify the air and surfaces. Some examples include:

- Self-cleaning facade coatings that break down airborne pollutants and keep surfaces cleaner for longer.

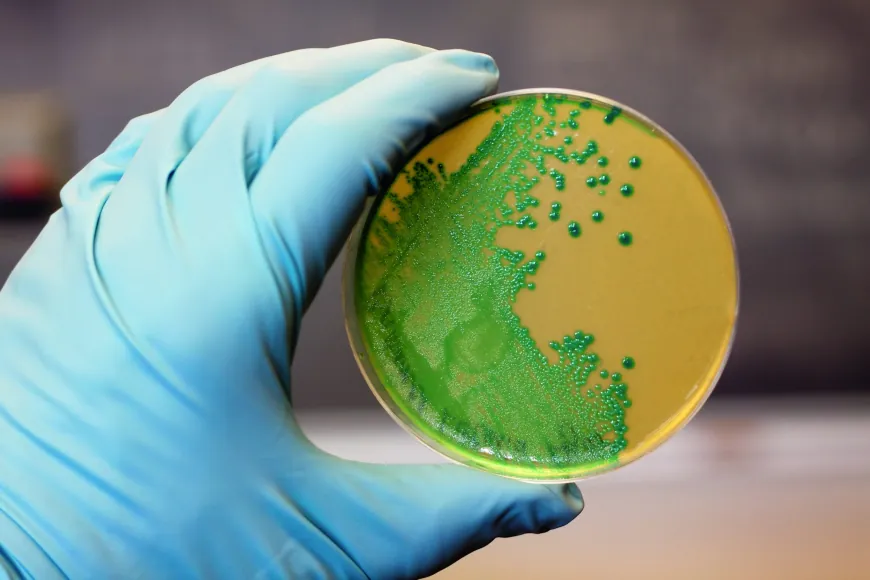

- Anti-microbial interior wall, floor and ceiling coatings that inactivate viruses, bacteria, mold and mildew.

- Anti-smog coatings for windows, skylights and solar panels that oxidize NOx gases from vehicle emissions.

- Deodorizing coatings for restrooms, locker rooms, elevators and trash rooms that eliminate odors at source.

- Air purifying coatings on HVAC systems and ductwork that help sterilize circulated indoor air.

Advantages over Conventional Cleaning Methods

When compared to traditional manual cleaning methods, self-cleaning coatings offer several advantages for indoor environmental quality:

- Continuous cleansing action works passively as long as there is light, requiring no additional chemicals, water or labor.

- Can break down a wide spectrum of pollutants more thoroughly at molecular levels.

- Help combat source of odors, dirt buildup, mold and microbial growth for improved hygiene.

- Self-sterilizing effect on coated surfaces helps raise standards of cleanliness amid COVID-19 pandemic.

- Low maintenance and durable coatings can last 5-10 years with no reapplication needed.

- Energy savings by reducing regular cleaning schedules and costs over the long-term.

Applications in Other Industries

Besides buildings and construction, Photocatalytic Coating are finding several other environmental applications:

- Purification of drinking and wastewater via coatings on filtration membranes and collection pools. Catalysis helps deactivate pathogens and chemical contaminants.

- Air filtration coatings on furnace and AC unit components that continuously scrub passing air of various pollutant gases.

- Anti-smog coatings on exterior building facade materials, vehicles, road and bridge surfaces to reduce air pollution in dense urban environments.

- Self-disinfecting coatings for surfaces in hospitals, medical devices and other healthcare facilities to curb spread of infections.

- Food packaging and storage containers with self-cleaning coatings extend product shelf life by slowing microbial decay.

- Self-cleaning solar panels that stay cleaner for higher efficiency by photodegrading organic residue buildup.

Market Growth Projections

The global Photocatalytic Coating industry size was valued at $1.2 billion in 2019 and is expected to expand at a CAGR of over 12% from 2020 to 2027. Rapid growth is anticipated as these eco-friendly products gain wider acceptance across residential, commercial and industrial verticals. The construction industry currently dominates demand for self-cleaning, air purifying and anti-microbial coating solutions. Government policies and regulations supporting air quality standards are also driving increased adoption. Moreover, ongoing R&D is helping widen the range of photocatalytic materials beyond titanium dioxide for tailored applications. This ongoing development supported by the inherent sustainability and performance advantages of the technology will likely see its market penetration deepen across multiple end use segments over the coming years.

Get more insights on Photocatalytic Coating

Unlock More Insights—Explore the Report in the Language You Prefer

About Author:

Ravina Pandya, Content Writer, has a strong foothold in the market research industry. She specializes in writing well-researched articles from different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc.