What is a Digital Twin and How Can It Benefit Different Industries?

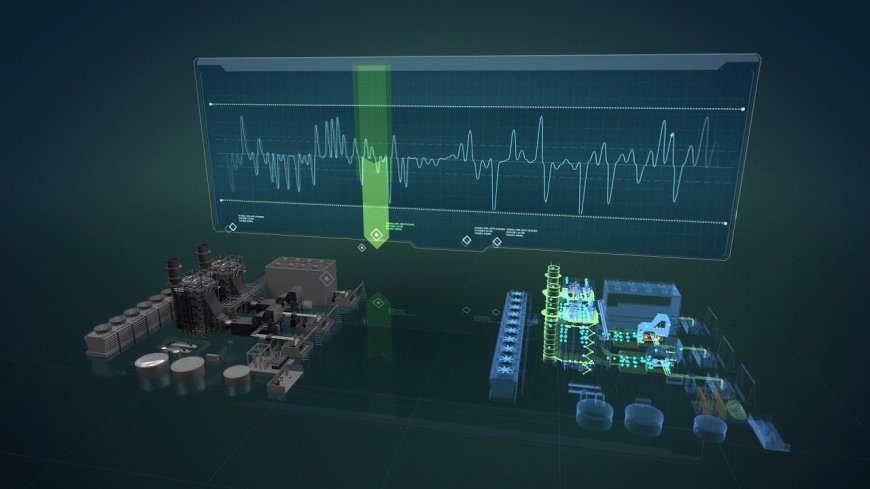

A digital twin refers to a digital replica of physical assets, processes and systems which can be used for various purposes.

A digital twin refers to a digital replica of physical assets, processes and systems which can be used for various purposes. A digital twin uses sensors and data to collect information about the physical twin and updates the digital version in real-time so they remain synchronized. By analyzing the data from them, it is possible to monitor the physical asset, optimize processes and predict issues before they occur in reality. They offer significant value across many industries by enabling simulations, testing scenarios and decision making without impacting the physical assets.

Applications in Manufacturing

Manufacturing is one of the major sectors benefiting from them. Automakers can create Digital Twin of their vehicles to test new designs virtually before producing physical prototypes. This allows testing different component combinations, crash simulations and evaluating performance efficiently without wasting resources. They are also helpful for modeling manufacturing plants and processes. Issues like bottlenecks, inefficiencies and quality problems can be identified by simulating digital versions of production lines and operations. Manufacturers can evaluate process improvements, equipment upgrades and layout changes virtually using them before implementing changes on the actual production floor. This saves costs on physical rework and downtime. They even allow remote monitoring of manufacturing equipment for predictive maintenance.

Use in Infrastructure Management

Buildings, bridges and other infrastructure assets can have them created for management purposes. Cities are using them to model traffic patterns, population density and infrastructure interdependencies to aid urban planning. Digital replicas of buildings allow facilities managers to monitor energy usage, detect issues and improve maintenance planning. Utilities leverage them of power grids and transmission networks for distribution optimization, outage prevention and disaster response planning. Digital twins of bridges and tunnels help structural engineers evaluate load capacities, detect stress points and schedule necessary repairs in a cost-effective way. This ensures public infrastructure stays safe and functional through its entire lifecycle.

Applications for Healthcare

The healthcare sector is revolutionizing care delivery with them. Hospitals can create digital copies of patients to run simulations of surgeries, evaluate different treatment options and catch any errors or risks before operating on real people. Digital twins of organs and physiological systems allow medical researchers to test new drugs and therapies virtually. This speeds up research and reduces risks of human trials. Custom-built digital twins even help train medical students through simulations. Overall, they have the potential to make personalized medicine a reality by offering customized virtual models of individual patients. This will enhance diagnostics, deliver more precise care protocols and improve health outcomes.

Benefitting Products and Supply Chains

Product companies leverage them across the entire value chain from design to after-sales support. During design, digital representations allow evaluating design changes, certifications and regulations virtually before finalizing the physical product. In manufacturing, they optimize production planning, quality monitoring and equipment services. For products themselves, they enable remote monitoring, predictive maintenance, usage analytics and personalization. In supply chains, virtual replicas optimize logistics, inventory management, warehousing and distribution channel planning. They even support remote troubleshooting and repairs during product usage eliminating need for on-site servicing in many cases. Overall, they streamline products, manufacturing and supply chains.

Enabling Smart Cities and Infrastructure

They are core to developing smart connected cities and infrastructure. Urban planners leverage virtual simulations of entire regions to model traffic patterns, resource usage, environmental impact and infrastructure interdependencies. This helps optimally allocate resources, improve services and plan for future growth seamlessly. Digital twins of power grids, communication networks and utility systems enable monitoring usage, detecting issues proactively and coordinating inter-agency emergency response. They support services like smart lighting, waste management and resilient disaster recovery planning. Citizens also benefit through applications monitoring air quality, optimizing commutes and engaging civic participation. When aggregated, they become smart digital replicas powering next-gen living, working and governance in smart cities.

Get more insights on Digital Twin

Get More Insights—Access the Report in the Language that Resonates with You

About Author:

Money Singh is a seasoned content writer with over four years of experience in the market research sector. Her expertise spans various industries, including food and beverages, biotechnology, chemical and materials, defense and aerospace, consumer goods, etc. (https://www.linkedin.com/in/money-singh-590844163)