Why Dynamic Balancing Is Essential for Machinery Health

Learn why dynamic balancing is critical for machinery health. Discover how it reduces vibration, extends equipment life, and prevents costly breakdowns.

Let me paint you a picture.

You’re standing on the factory floor, everything humming along just fine—until it isn’t. A bearing overheats. A motor starts vibrating like it’s dancing to its own beat. Before long, production halts, technicians scramble, and the clock starts ticking on costly downtime.

Now, rewind. What if I told you a simple, often-overlooked service could’ve prevented this?

Enter dynamic balancing.

The Hidden Culprit Behind Wear and Tear

Here’s the thing: even the most precisely engineered rotating equipment—fans, shafts, rotors, impellers—can fall out of balance over time. Maybe it’s material buildup. Maybe it’s wear and tear. Maybe it was never perfectly balanced in the first place. But once an imbalance sets in, it creates a chain reaction.

Small vibrations become big problems.

Unbalanced parts shake. Bearings wear out faster. Bolts loosen. Motors work harder than they should. What you’re left with is a machine that’s not only inefficient, but living on borrowed time.

I once visited a facility where a 10-horsepower motor fan had developed a subtle vibration. Nothing wild—just a low hum you could feel if you placed your hand on the housing. A few weeks later, it seized. Post-mortem analysis? Unbalance led to excessive radial load, which cooked the bearing. Total avoidable failure.

So, What Is Dynamic Balancing?

Imagine a car tire with a lead weight added to one side of the rim. Why do we do that? Because even the smallest imbalance can cause a shaky ride, worn-out tread, and steering issues.

The same principle applies to industrial machinery.

Dynamic balancing is the process of measuring and correcting imbalance in rotating components—while they’re spinning. It's different from static balancing, which is done while the part is stationary. Dynamic balancing takes into account real-world operating conditions, allowing technicians to pinpoint where and how much weight needs to be adjusted to achieve true balance.

It’s like chiropractic care for your equipment—finding misalignments and correcting them before bigger issues surface.

The Ripple Effect of a Well-Balanced Machine

When your machinery is balanced, a lot of good things happen:

-

Longer Bearing Life: Bearings are the first to suffer from vibration. Balance them out, and you’ll dramatically reduce wear.

-

Quieter Operation: A smoother machine is a quieter machine. That hum or rattle you’ve been ignoring? It’s not normal.

-

Energy Efficiency: Balanced machines don’t have to fight against their own inertia. That means less power draw and lower utility bills.

-

Fewer Shutdowns: Reduced vibration means fewer emergency stops, maintenance calls, and unplanned production halts.

-

Better Product Quality: In industries where precision matters (think aerospace or automotive), imbalance can lead to subpar output or even rejections.

The cost of not balancing? It creeps up on you in repairs, energy use, and downtime until you’re wondering why your once-reliable machine now feels like a lemon.

Not Just for the Big Guys

You might be thinking, “That’s great, but we’re a small shop. Do we really need this?”

Yes. You do.

Dynamic balancing isn’t reserved for massive factories or aerospace operations. Even small shops running fans, pumps, or CNC spindles benefit from balancing. In fact, smaller operations often feel the pain of equipment failure more acutely—because every hour lost hits harder.

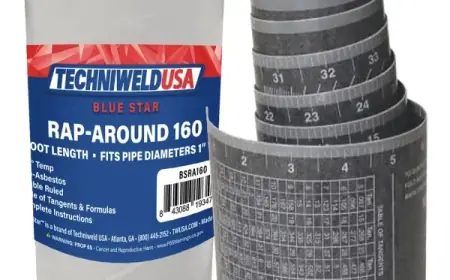

Balancing can be done on-site or in-shop, and the tools are more accessible than ever. From portable field balancers to precision balancing machines, there's a solution for almost every budget and scenario.

When to Balance

Here’s a simple rule of thumb: if it spins, it should be balanced—especially if it vibrates.

Some common signs your equipment may need dynamic balancing include:

-

Unusual noise or vibration

-

Premature bearing failure

-

Increased energy usage

-

Excessive wear on couplings or belts

-

Overheated motors

-

Loosened fasteners or mounts

And don’t just wait for the symptoms. Make balancing a proactive part of your preventative maintenance schedule. It’s like brushing your teeth—you don’t wait for a cavity to start flossing.

Final Thoughts

In the world of industrial maintenance, dynamic balancing is a bit like tire rotation: it’s easy to overlook, but it makes everything else work better and last longer.

It’s not the flashiest service. It won’t win you awards. But it will save you money, reduce downtime, and extend the life of your machines. And if you’ve ever dealt with the chaos of an unexpected equipment failure, that’s more than enough reason to make it a regular practice.

So next time something feels “off” on the shop floor—or even before it does—consider balancing. Your machinery will thank you. Quietly.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0