What is a laser machine for metal and how does it work in industrial applications

A laser machine for metal is a high-precision tool used in industrial and manufacturing sectors to cut, engrave, mark, or weld various types of metal materials using concentrated laser beams.

A laser machine for metal is a high-precision tool used in industrial and manufacturing sectors to cut, engrave, mark, or weld various types of metal materials using concentrated laser beams. These machines use a powerful laser to generate intense heat that melts, burns, or vaporizes the metal at specific points, creating clean, accurate cuts and designs without physical contact.

Types of Laser Machines for Metal

There are several types of laser machines designed for working with metal, including:

-

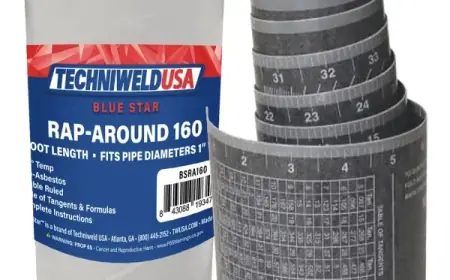

Fiber Laser Machines: Most commonly used for cutting and engraving metals. They have a long service life, low maintenance costs, and deliver excellent cutting performance, especially on stainless steel, carbon steel, aluminum, copper, and brass.

-

CO₂ Laser Machines: Typically used for non-metallic materials but can cut thin metals if equipped with special enhancements. They are more suited for general-purpose applications.

-

Nd:YAG Laser Machines: Often used for precision welding and engraving on metal surfaces. They are effective for fine-detail work like in the electronics and jewelry industries.

How It Works

A metal laser machine works by directing a high-power laser beam onto the surface of the metal. The laser beam is focused through a lens, creating a tiny focal point where the energy density is high enough to melt or vaporize the material. Depending on the process, an assist gas like nitrogen, oxygen, or air is used to blow away the molten material, enhancing the cut quality and speed.

-

Cutting: The laser follows a programmed path to cut shapes, holes, or outlines in metal sheets.

-

Engraving: Lower power settings allow for detailed markings, text, or logos without cutting through the material.

-

Welding: The laser melts metal edges so they fuse together, often used in automotive and aerospace manufacturing.

Advantages

-

Precision: Laser machines offer extremely high accuracy, capable of cutting intricate shapes with minimal error.

-

Speed: They are faster than traditional cutting tools, making them ideal for high-volume production.

-

Versatility: Suitable for a wide range of metals and thicknesses.

-

Minimal Waste: Because of the precision and control, there is less material loss and minimal need for post-processing.

-

Automation Friendly: Can be integrated with CAD/CAM systems and robotic arms for full automation.

Common Applications

-

Automotive Industry: Cutting and welding parts for vehicles.

-

Construction: Fabricating structural components from steel or aluminum.

-

Jewelry Making: Engraving and fine detail cutting.

-

Electronics: Marking serial numbers or cutting small metal parts.

-

Medical Devices: Manufacturing precise surgical tools and implants.

Conclusion

Laser machines for metal are transformative tools in modern manufacturing, offering unmatched precision, efficiency, and versatility. Whether you're cutting thick steel plates or engraving a fine design onto a piece of jewelry, laser machines provide a clean and effective solution. Their ability to automate and produce consistent results makes them a top choice for industries aiming to optimize production and maintain high quality standards.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0