Unveiling the Secrets of 2-Ethylhexyl Acrylate Production Process

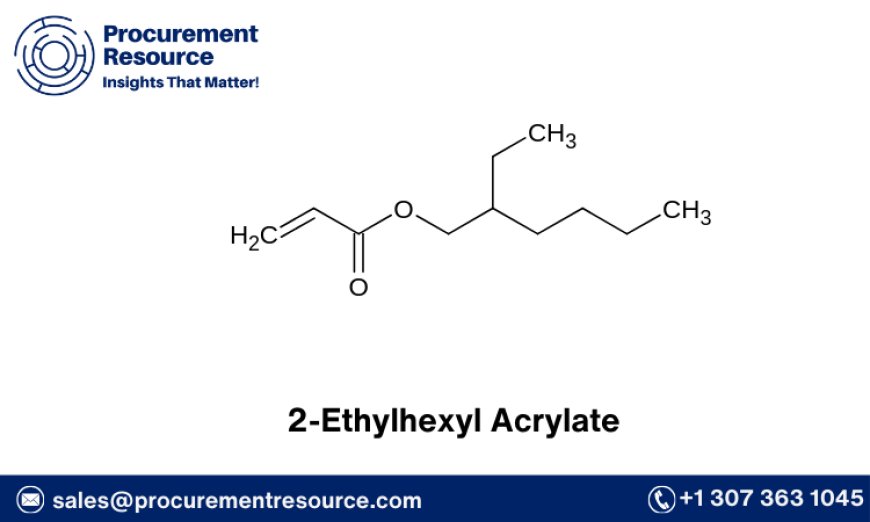

2-Ethylhexyl acrylate (2-EHA) is a vital raw material in the production of acrylic polymers and copolymers.

2-Ethylhexyl acrylate (2-EHA) is a vital raw material in the production of acrylic polymers and copolymers. These substances find extensive applications in adhesives, coatings, sealants, and elastomers due to their excellent flexibility, durability, and resistance to various environmental factors. Understanding the production process of 2-Ethylhexyl acrylate is crucial for manufacturers aiming to optimize their operations and remain competitive in the market.

2-Ethylhexyl Acrylate Production Cost

The production cost of 2-Ethylhexyl acrylate involves several components, including raw materials, energy consumption, labor, and overheads. The primary raw materials for producing 2-EHA are acrylic acid and 2-ethylhexanol. The cost of these raw materials, along with the efficiency of the production process, significantly impacts the overall cost structure. Additionally, energy costs, labor wages, and overhead expenses such as maintenance and utilities contribute to the production cost.

Request For Sample: https://www.procurementresource.com/production-cost-report-store/2-ethylhexyl-acrylate/request-sample

Economic factors, market demand, and supply chain dynamics also influence the production cost. Fluctuations in the prices of raw materials, particularly acrylic acid and 2-ethylhexanol, directly affect the cost of production. Efficient production processes and technological advancements can help mitigate these costs and improve profit margins for manufacturers.

Manufacturing Report and Process

The manufacturing process of 2-Ethylhexyl acrylate involves the esterification of acrylic acid with 2-ethylhexanol. This process is typically carried out in the presence of a catalyst and involves several key steps:

-

Preparation of Reactants: Acrylic acid and 2-ethylhexanol are purified to remove any impurities that might affect the reaction. High-purity reactants ensure a more efficient and higher yield process.

-

Esterification Reaction: The purified reactants are mixed in a reactor vessel along with a catalyst. Commonly used catalysts include sulfuric acid, p-toluenesulfonic acid, or strong acid ion-exchange resins. The reaction mixture is heated to a specific temperature to facilitate the esterification reaction, forming 2-Ethylhexyl acrylate and water as a byproduct.

-

Separation and Purification: The reaction mixture is then subjected to distillation to separate 2-Ethylhexyl acrylate from the byproducts and unreacted materials. Fractional distillation is commonly employed to achieve high purity of the final product.

-

Quality Control: The purified 2-Ethylhexyl acrylate undergoes rigorous quality control tests to ensure it meets industry standards and specifications. Parameters such as purity, acid value, and color are typically assessed.

-

Packaging and Storage: The final product is then packaged in appropriate containers and stored under suitable conditions to maintain its quality until it reaches the end-users.

Raw Material Costs

The primary raw materials for producing 2-Ethylhexyl acrylate are acrylic acid and 2-ethylhexanol. The cost of these raw materials significantly influences the overall production cost. Let's take a closer look at these components:

Acrylic Acid

Acrylic acid is a key feedstock in the production of 2-EHA. It is derived from propylene, a byproduct of petroleum refining and ethylene production. The price of acrylic acid is subject to fluctuations based on crude oil prices, supply-demand dynamics, and production capacities. Manufacturers often need to secure stable and cost-effective sources of acrylic acid to maintain profitability.

2-Ethylhexanol

2-Ethylhexanol is another crucial raw material used in the esterification process. It is produced from butyraldehyde, which in turn is derived from propylene. Similar to acrylic acid, the price of 2-ethylhexanol is influenced by crude oil prices and market demand. Efficient procurement and supply chain management of 2-ethylhexanol are essential for cost control.

Catalyst and Additives

The catalysts and additives used in the production process also contribute to the raw material costs. While their proportion in the overall cost structure might be relatively smaller, selecting the right catalyst can improve process efficiency and product quality, thereby impacting the total production cost.

Latest News Update

Technological Advancements

Recent advancements in production technologies and process optimization have played a significant role in reducing the cost of 2-Ethylhexyl acrylate production. Innovations such as the use of more efficient catalysts, improved reactor designs, and enhanced distillation techniques have contributed to higher yields and lower energy consumption, thereby reducing the overall production cost.

Market Trends

The 2-Ethylhexyl acrylate market has witnessed significant growth in recent years, driven by increasing demand from the adhesives, coatings, and plastics industries. Market analysts predict continued growth, with a focus on sustainable and eco-friendly production processes. Manufacturers are exploring green chemistry approaches and renewable raw materials to align with environmental regulations and consumer preferences.

Impact of Raw Material Prices

Fluctuations in the prices of acrylic acid and 2-ethylhexanol continue to impact the production cost of 2-EHA. For instance, any disruption in the supply chain or changes in crude oil prices can lead to volatility in raw material costs. Manufacturers are increasingly adopting strategies such as long-term contracts and diversifying suppliers to mitigate these risks.

Regulatory Developments

Regulatory changes, particularly those related to environmental and safety standards, can influence the production cost and market dynamics of 2-Ethylhexyl acrylate. Compliance with stringent regulations often requires additional investments in technology and process modifications, affecting the overall cost structure. Staying updated with regulatory developments and proactively adapting to changes is crucial for manufacturers to maintain competitiveness.

Strategic Partnerships

Strategic partnerships and collaborations among manufacturers, suppliers, and research institutions are emerging trends in the 2-Ethylhexyl acrylate industry. These partnerships aim to enhance research and development efforts, improve production efficiency, and ensure a stable supply of raw materials. Collaborative initiatives are expected to drive innovation and cost-effective production processes in the coming years.

Conclusion

Understanding the production cost of 2-Ethylhexyl acrylate is vital for manufacturers and stakeholders in the chemical industry. The cost structure is influenced by various factors, including raw material prices, production efficiency, and regulatory compliance. Technological advancements and strategic partnerships offer opportunities to optimize production processes and reduce costs. Staying abreast of market trends and regulatory developments is essential for maintaining competitiveness and ensuring sustainable growth in the 2-EHA market.

hollandsmith157@gmail.com

hollandsmith157@gmail.com