Understanding the Principle Behind the Bursting Strength Tester

In today’s competitive packaging industry, ensuring material strength is critical to maintaining product integrity throughout storage and transport. One of the most reliable instruments for assessing this quality is the Bursting Strength Tester. This precision tool plays a vital role in determining how much pressure a packaging material like paper, cardboard, or fabric can withstand before it ruptures.

In today’s competitive packaging industry, ensuring material strength is critical to maintaining product integrity throughout storage and transport. One of the most reliable instruments for assessing this quality is the Bursting Strength Tester. This precision tool plays a vital role in determining how much pressure a packaging material like paper, cardboard, or fabric can withstand before it ruptures.

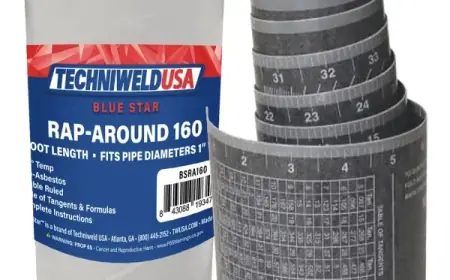

The bursting strength tester principle is based on hydraulic pressure. A circular rubber diaphragm, clamped tightly between the sample, exerts increasing pressure via hydraulic fluid until the material bursts. The pressure at which the material fails is recorded as its bursting strength, typically measured in kg/cm².

This method ensures accurate simulation of real-world conditions where packaged goods are exposed to compressive and multidirectional stresses. The simplicity of this principle allows for high repeatability and reliability, making it a preferred choice across industries.

Modern advancements have introduced Linux bursting strength testers, which are equipped with microprocessor-based controllers and run on Linux-powered embedded systems. These versions offer high-speed data processing, user-friendly interfaces, and enhanced calibration options. The Linux OS backbone provides stability, better memory management, and real-time testing updates with improved error diagnostics.

Key Features of Advanced Bursting Strength Testers

-

Digital Display with Peak Hold – Advanced models provide real-time peak value display with digital accuracy.

-

Sturdy Construction – Precision-engineered to eliminate vibration and allow consistent pressure application.

-

Automatic Clamping Mechanism – Ensures consistent sample holding, removing operator bias.

-

Memory Storage – Some Linux-based testers can store historical test data for audits or comparison.

-

Safety Features – Emergency stop and overload protection enhance user and equipment safety.

With the integration of Linux systems, the bursting strength tester becomes more than just a mechanical device—it transforms into an intelligent quality control solution capable of streamlining data acquisition and analysis.

Diverse Applications and Uses of Bursting Strength Testers

Bursting strength tester uses extend across multiple sectors, particularly where packaging durability is crucial. Some of the most common applications include:

-

Corrugated Box Manufacturing: Ensures that shipping boxes meet the pressure resistance required for logistics.

-

Paper & Board Production: Measures the mechanical properties of raw materials to classify grades and quality.

-

Textile Industry: Determines the bursting capacity of fabrics, especially technical textiles used in protective wear.

-

Plastic Film Testing: Used for checking the rupture strength of plastic sheets used in flexible packaging.

-

Leather & Synthetic Sheets: Evaluates the resistance of materials used in upholstery and fashion accessories.

Each industry tailors the test conditions slightly based on the material, yet the fundamental bursting principle remains consistent.

Benefits of Using a Linux Bursting Strength Tester

Upgrading to a Linux bursting strength tester brings several operational advantages:

-

High Precision Testing: The embedded system enables advanced algorithms for more accurate and repeatable readings.

-

Customizable Interface: Touchscreen displays with Linux OS allow user-defined testing profiles and result formats.

-

Seamless Integration: Connectivity with printers and PCs via USB or Ethernet enhances data logging and reporting.

-

Minimal Downtime: Robust system architecture reduces the chances of OS crashes, improving machine uptime.

The use of open-source software like Linux also means updates and new features can be rolled out more efficiently, with enhanced security and system control.

Final Thoughts

In an era where packaging quality defines brand reputation, the bursting strength tester proves to be an indispensable asset. Whether it’s a basic analog tester or a modern Linux-driven variant, this equipment ensures materials meet the stringent standards of global supply chains. Its wide applications, grounded principle, and evolving technology make it a cornerstone of quality control labs across industries.

If your business involves packaging or raw material conversion, investing in a technologically advanced bursting strength tester is not just a quality decision—it’s a strategic one.

Get the Best Bursting Strength Tester for Your Needs

For advanced, reliable, and high-precision testing equipment, reach out to our experts today.

? Call us at: +91 9210 903 903

? Email: [email protected]

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0