How Cryocooler is Different from a Refrigerator?

Discover the key differences between cryocoolers and refrigerators! Learn how these cooling systems work, their unique applications, and why cryocoolers are ideal for ultra-low temperatures.

Cryocooler is a small closed-cycle refrigerator or simply a machine that can reach cryogenic temperatures. Cryogenics starts at temperatures below -153 degrees Celsius.

The difference between a cryocooler and a refrigerator is that, a cryocooler or cryo-refrigerator is a machine that generates a very low temperature in the cryogenics range, whereas a refrigerator generates a low temperature in the refrigeration range. The gas working in the cryocooler is known as cryogen while it is known as a refrigerant for the refrigerator.

Regenerative and Recuperative Heat Exchanger

Heat exchange is a device that improves heat transfer and it is an important component of the cryocooler. It is available in a variety of sizes, types, arrangements, and shapes.

Regenerative

In the regenerative heat exchanger, cold and warm flows pass through the regenerator at different phases of the cycle, then the heat from the warm stream is absorbed by the refrigerator and dispatched into the cold stream. Regenerative heat exchanger usually results in oscillating flows, and it is very common in cryocooler cycles.

Recuperative

In the recuperative heat exchanger, each fluid flow path is separated by a wall. The fluids flow simultaneously via the exchanger switching heat across the wall. This heat exchanger allows continuous flows, and it is very common in large cryogenic refrigerators.

Benefits of Cryocooler in Healthcare Industry

Cryocoolers have a great impact on the healthcare industry, mainly in PET, MRI, and various other large or small healthcare applications. For instance, preclinical applications and metabolic imaging would not be possible without using cryocoolers.

Cryocooler is sustainable and reduces carbon footprint, for example, in MRI systems because of its ability to significantly re-condense helium and other refrigerants.

The increasing capacity of cryocooler cooling power and their industrial robustness continue to advance their usability in various healthcare applications.

Uses of Cryocooler

Cryocooler is Vastly Used in the Aerospace and Defense Industry

There are various applications of cryocoolers such as in, aerospace and defense, healthcare, semiconductor and electronics, energy, environmental monitoring, agriculture & biology, nuclear, mining and metals, and transportation. Let’s dive into details for some of these applications.

Cryocooler is vastly used in the defense and aerospace industry, such as cooling infrared sensors in satellites or missile guidance systems. These machines are used in space telescopes and satellites to keep their sensors extremely cold so that they can capture images on long-duration missions. These sensors require extremely low temperatures to capture images, and if the sensors did not reach cryogenic temperatures, then it would not be possible.

The semiconductor fabrication industry also used cryocooler, because of the increasing sales of semiconductors and the reduced costs of large-scale fabrication processes.

Cryocooler is also used in cryopreservation. Cryopreservation is the process of preserving tissues, organelles, cells, or other biological constructs by cooling the samples at a very low temperature. Another use of cryocooler is in the mining and metal sectors, it is used to avoid corrosion and wear resistance.

Conclusion

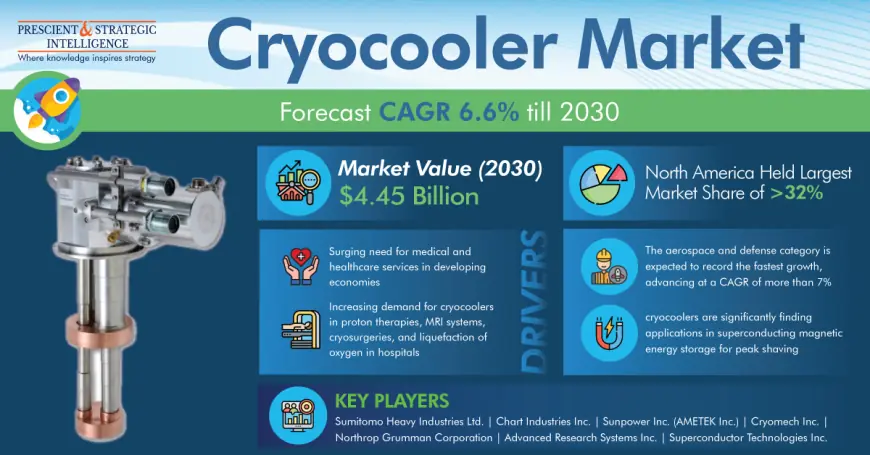

Due to the increasing uses of cryocoolers in various operations, for example, in the aerospace and defense industry, healthcare industry, and semiconductor fabrication industry, the demand for this machine will continue to rise in the years to come. As a result of this, the cryocooler industry is likely to generate a revenue of USD 4.45 billion by the end of this decade.