Exploring the Applications of Methyl Vinyl Ketone in Various Industries

Methyl Vinyl Ketone (MVK) is a highly reactive and versatile chemical compound, extensively utilized in numerous industrial applications. This article delves into the myriad uses of MVK across different sectors, highlighting its significance and the advantages it brings to each industry.

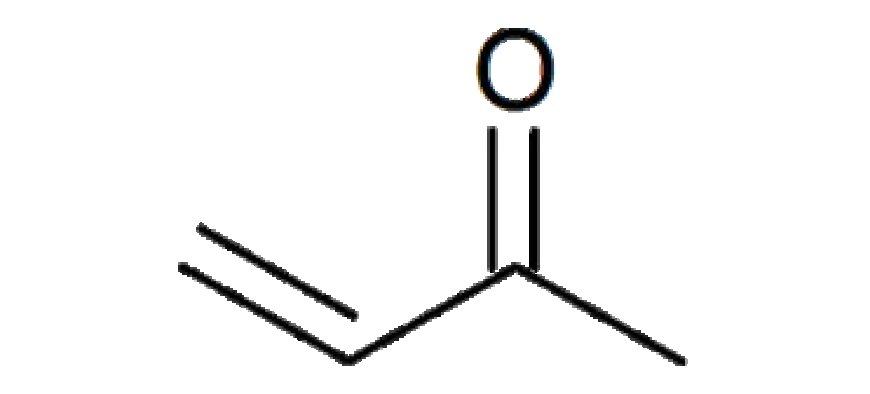

Understanding Methyl Vinyl Ketone

Methyl Vinyl Ketone (MVK), also known as butenone, is a colorless liquid with a pungent odor. It is an organic compound with the chemical formula C4H6O. MVK is known for its reactivity, making it a valuable intermediate in various chemical reactions and industrial processes.

Applications in the Chemical Industry

Intermediate in Organic Synthesis

MVK serves as a critical intermediate in the synthesis of various organic compounds. Its high reactivity allows it to participate in numerous chemical reactions, facilitating the production of a wide range of chemicals used in pharmaceuticals, agrochemicals, and polymers. For instance, MVK is employed in the synthesis of steroids, vitamins, and other complex organic molecules.

Production of Polymers

In the polymer industry, MVK is utilized to manufacture specialized polymers with unique properties. These polymers find applications in adhesives, coatings, and elastomers. The incorporation of MVK into polymer chains enhances their thermal stability, mechanical strength, and resistance to environmental factors, making them suitable for demanding applications.

Role in the Pharmaceutical Industry

Synthesis of Active Pharmaceutical Ingredients (APIs)

MVK plays a pivotal role in the pharmaceutical industry as a building block for the synthesis of Active Pharmaceutical Ingredients (APIs). Its reactivity and ability to form diverse chemical bonds make it an essential component in the development of drugs. MVK is involved in the production of antibiotics, anti-inflammatory drugs, and various other therapeutic agents.

Pharmaceutical Research and Development

Researchers in the pharmaceutical sector leverage MVK for the development of new drug candidates. Its versatility allows scientists to create novel compounds with potential therapeutic benefits. By modifying the MVK structure, researchers can design molecules with improved efficacy, reduced side effects, and enhanced bioavailability.

Importance in the Agrochemical Sector

Herbicides and Pesticides

MVK is a key ingredient in the formulation of herbicides and pesticides. Its reactivity enables the creation of compounds that can effectively control weeds and pests, safeguarding crop yields and ensuring food security. The use of MVK-derived agrochemicals contributes to sustainable agricultural practices by reducing crop losses and minimizing the need for excessive chemical inputs.

Plant Growth Regulators

In addition to pest control, MVK is employed in the production of plant growth regulators. These substances influence various physiological processes in plants, such as growth, flowering, and fruiting. By utilizing MVK-based growth regulators, farmers can optimize crop production, enhance quality, and improve harvest timing.

Applications in Material Science

Development of Advanced Materials

The unique properties of MVK make it an invaluable component in the development of advanced materials. Researchers use MVK to synthesize materials with specific characteristics, such as increased strength, flexibility, and durability. These materials find applications in aerospace, automotive, and construction industries, where high-performance materials are essential.

Functional Coatings

MVK is also used in the production of functional coatings. These coatings provide surfaces with protective, decorative, or functional properties. For example, MVK-based coatings can enhance corrosion resistance, improve adhesion, and impart antimicrobial properties. Such coatings are widely used in the manufacturing of consumer goods, electronics, and medical devices.

Environmental and Safety Considerations

Handling and Storage

Given its reactivity, MVK must be handled with care to ensure safety. Proper storage conditions, such as cool and well-ventilated areas, are crucial to prevent accidental reactions. The use of appropriate personal protective equipment (PPE) is also necessary when handling MVK to avoid exposure and potential health risks.

Environmental Impact

While MVK offers numerous industrial benefits, it is essential to consider its environmental impact. Efforts are being made to develop sustainable production methods and minimize the release of MVK into the environment. By implementing stringent regulations and adopting green chemistry principles, the industry aims to mitigate the ecological footprint of MVK-related processes.

Future Prospects of Methyl Vinyl Ketone

Innovation in Chemical Synthesis

The future of Methyl vinyl ketone manufacturers in various industries looks promising, with ongoing research focusing on innovative chemical synthesis methods. Advances in catalysis and reaction engineering are expected to enhance the efficiency of MVK-based processes, leading to the development of new materials and compounds with unprecedented properties.

Sustainable Practices

Sustainability is a growing concern across all industries, and the use of MVK is no exception. Researchers are exploring eco-friendly alternatives and renewable sources for MVK production. By adopting sustainable practices, industries can reduce their reliance on fossil fuels and minimize the environmental impact of MVK-related activities.

Expanding Applications

As scientific understanding of MVK continues to grow, new applications are likely to emerge. The compound's versatility and reactivity make it a candidate for use in cutting-edge technologies, such as nanomaterials, biotechnology, and renewable energy solutions. These expanding applications will further solidify MVK's role as a vital component in the modern industrial landscape. The sulfur trioxide pyridine complex is a versatile reagent used in organic synthesis for the selective sulfonation of aromatic compounds. Careful handling of the sulfur trioxide pyridine complex is required due to its reactive nature and the potential for the release of sulfur trioxide gas.

Conclusion

Methyl Vinyl Ketone (MVK) is an indispensable chemical compound with a wide range of applications across various industries. From its role in organic synthesis and polymer production to its significance in pharmaceuticals, agrochemicals, and material science, MVK's versatility and reactivity make it a valuable asset. By understanding and harnessing the potential of MVK, industries can continue to innovate and develop sustainable solutions for the future. Trimethylsilyl trifluoromethanesulfonate, also known as TMSOTf, is a powerful silylating agent used in organic synthesis for the protection of alcohols and other hydroxyl-containing compounds.

lifechempharma

lifechempharma