Choosing the Right Train Bogie Manufacturer for Performance and Safety

That’s why our approach to Bogie Manufacturing combines advanced engineering with strict quality control to meet international expectations.

The bogie is among the most important constituents of railway safety and rationality. As an experienced Train Bogie Manufacturer, we at Syrontech understand that operators face growing challenges: durability, passenger comfort, compliance with global standards, and long-term cost efficiency.

That’s why our approach to Bogie Manufacturing combines advanced engineering with strict quality control to meet international expectations.

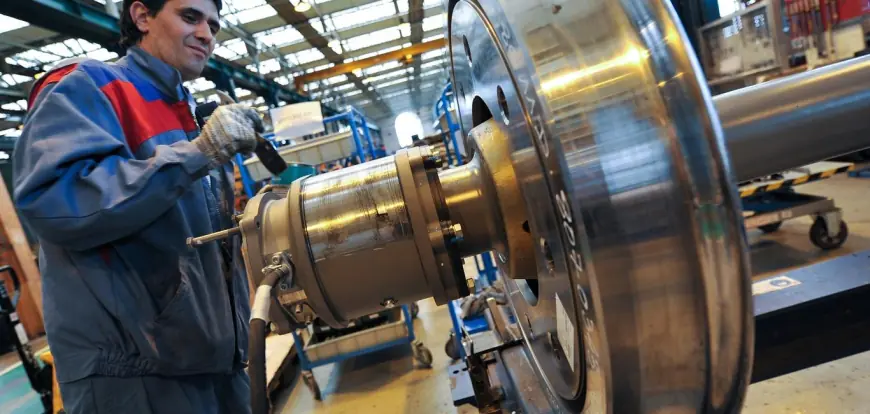

Why Train Bogies Are So Critical

A bogie is more than a wheelset. It forms the basis upon which the coach or wagon body is supported, providing stability, smooth movement, and braking. The ill-constructed bogies may lead to high maintenance expenditures, inconvenience to passengers, and even hazards. The decision on the partner to be used in Bogie Manufacturing has a direct effect on the fleet reliability in the long run.

We offer passenger and freight applications. Our bogies are precise, whether it is dealing with heavy axle loads, better ride comfort, or less noise at high speeds.

Technical Strengths That Set Us Apart

As a trusted Train Bogie Manufacturer, we focus on compliance with European and international railway standards. Every bogie is designed and tested to achieve safety and performance standards.

1. Structural Design

-

2-axle rigid frame bogies for freight applications

-

3-axle bogies for heavy cargo

-

Articulated bogies for high-speed passenger trains

2. Suspension Systems

-

Primary: coil springs with hydraulic dampers (stiffness range 8–15 MN/m)

-

Secondary: air springs or rubber-metal composites for improved ride quality

3. Material Selection

-

Welded durability steel alloys (S355J2G3).

-

Lightweight high-speed train aluminum alloys.

-

Forged steel axles (EN 13261 compliant) resistant to fatigue.

4. Performance Ratings

-

Axle load capacity: 22.5–32.5 tons for freight; 17–22 tons for passenger coaches

-

Speed capability: up to 200 km/h for passenger trains and 250+ km/h for high-speed fleets

-

Brake systems: disc brakes (640–750 mm) with cast iron or composite pads

5. Maintenance Cycles

-

Routine checks every 30,000–60,000 km

-

Overhaul cycle between 1.2–1.5 million km

These specifications make our bogies suitable for varied applications while lowering the lifetime cost of ownership.

Product Range

Bogies are designed and produced to suit freight or passenger operators.

-

Freight Bogies – Designed for maximum axle load tolerance and durability.

-

Passenger Bogies -Speedy and comfortable, sophisticated suspensions.

-

High-Speed Bogies – Lightweight, aerodynamic designs with superior safety systems.

Every price will come with compliance certification, technical documentation, and warranty coverage. Large quantities are subject to discounted prices.

Why Choose Syrontech as Your Train Bogie Manufacturer?

There are several global providers of Bogie Manufacturing, but clients choose us for:

-

Experience in engineering with international standards compliance (UIC, ISO, EN).

-

Custom solutions for freight, passenger, and high-speed networks.

-

Lower lifecycle costs through longer maintenance cycles and durable materials.

-

Proven track record with clients across multiple railway networks.

Safety, reliability, and affordability will assure railway operators that they can rely on every bogie we produce.

Addressing Industry Challenges

The contemporary railway operators face hard safety requirements, cost pressures and the necessity to obtain sustainable solutions. Our bogies are planned to accommodate high axle loads with low noise and vibration. In the case of passenger networks, we focus on comfort, where NMV is kept at or below 2.5 according to the UIC requirements. To freight operators, our bogies are more concerned with the high load capacity and less downtime.

Also, our solutions will be future-proof and compatible with ETCS/ATP systems; they can be adjusted to electrified and non-electrified routes.

FAQs About Train Bogie Manufacturing

Q1. What are the standards of your bogies?

Our bogies can meet UIC, ISO, and EN standards, thus ensuring international compatibility.

Q2. What is the maintenance frequency of bogies?

Regular inspections should be done after every 30,000-60,000 km, and a full overhaul is done after every 1.2 -1.5 million km.

Q3. Is it possible to customize bogies according to networks?

Yes, our bogies can be scaled to either standard gauge, broad gauge or narrow gauge.

Q4. How long are your bogies expected to last?

Our bogies provide 25-30 years of service with appropriate maintenance.

Q5. Do you offer after-sales services?

Yes, we offer technical documentation, supply of spares, and field support.

Final Thoughts

Any safe and efficient train is built around the bogie. Selecting a reputable Train Bogie Manufacturer yields decreased costs of operation, increased service life, and security. The basis of our relationship with Bogie Manufacturing is quality, compliance, and customer satisfaction.

? Interested in learning more? Get in touch with us or visit us today to have a detailed quotation.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0