The Versatility and Benefits of PC Hollow Sheets: A Comprehensive Guide

In the world of construction and design, materials that offer durability, versatility, and aesthetic appeal are highly sought after. One such material is the PC (Polycarbonate) hollow sheet. Known for its remarkable strength, lightweight nature, and transparency, Polycarbonate hollow sheet are becoming increasingly popular in various industries. This blog will delve into the features, benefits, applications, and reasons why PC hollow sheets are an excellent choice for numerous projects.

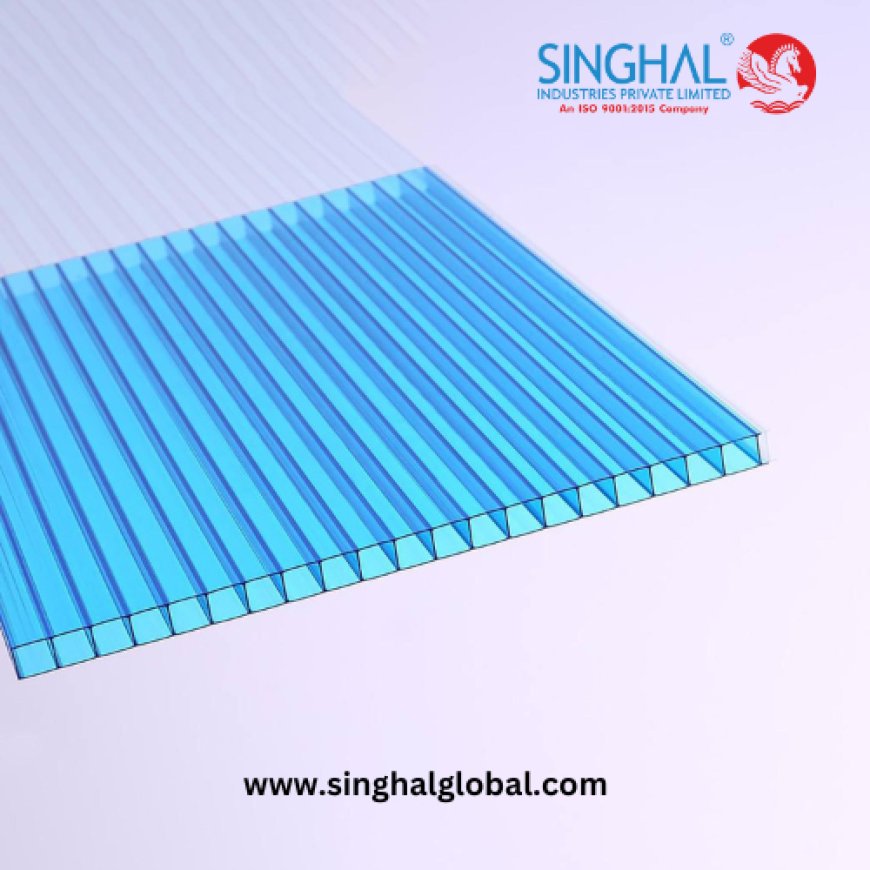

What are PC Hollow Sheets?

Polycarbonate hollow sheets are made from polycarbonate resin, a thermoplastic material renowned for its robustness and clarity. These sheets feature a hollow structure, consisting of two or more layers with air gaps in between. This design not only enhances their strength but also provides excellent Pp hollow sheet insulation. The hollow structure significantly reduces the weight of the sheets, making them easier to handle and install compared to solid polycarbonate or glass sheets.

Key Features of PC Hollow Sheets

1. Strength and Durability

PC hollow sheets are incredibly strong and impact-resistant. They can withstand significant physical stress without cracking or breaking, making them ideal for applications where durability is a primary concern. Unlike glass, polycarbonate is virtually unbreakable, providing a safer alternative for environments prone to impacts.

2. Lightweight

The hollow structure of these sheets makes them much lighter than solid polycarbonate or glass sheets. This reduced weight translates to easier handling, transportation, and installation, which can lead to lower labor costs and faster project completion times.

3. Transparency

Polycarbonate hollow sheets offer excellent light transmission, similar to that of glass. They are available in various levels of transparency, allowing designers and architects to choose the right balance of light diffusion and privacy for their specific needs.

4. Thermal Insulation

The air gaps within the hollow structure provide superior thermal insulation. This characteristic helps maintain consistent indoor temperatures, reducing the need for additional heating or cooling and thereby contributing to energy efficiency.

5. UV Protection

PC hollow sheets are often treated with UV-resistant coatings, which protect them from the harmful effects of ultraviolet radiation. This UV protection not only extends the lifespan of the sheets but also prevents yellowing and degradation over time.

6. Flexibility

Polycarbonate sheets are highly flexible, making them suitable for various design applications. They can be easily curved or bent to fit specific architectural designs without compromising their structural integrity.

Benefits of Using PC Hollow Sheets

1. Cost-Effectiveness

Due to their lightweight nature, PC hollow sheets are easier and cheaper to transport and install compared to traditional materials like glass. Additionally, their durability means fewer replacements and repairs, further reducing long-term costs.

2. Energy Efficiency

The thermal insulation properties of PC hollow sheets help in maintaining indoor temperatures, leading to reduced energy consumption for heating and cooling. This energy efficiency is beneficial for both residential and commercial buildings, contributing to lower utility bills and a smaller carbon footprint.

3. Safety

The high impact resistance of polycarbonate makes PC hollow sheets a safer option than glass, especially in areas prone to severe weather conditions or vandalism. Their shatterproof nature reduces the risk of injury from broken pieces.

4. Versatility in Applications

From roofing and skylights to greenhouse construction and advertising signs, PC hollow sheets can be used in a wide range of applications. Their versatility extends to both functional and aesthetic purposes, making them a favorite among architects and builders.

5. Aesthetic Appeal

With their clear, smooth surface, PC hollow sheets provide a modern and sleek look to any structure. They are available in various colors and finishes, allowing for creative and customized design solutions.

6. Environmental Impact

Polycarbonate is a recyclable material, which makes PC hollow sheets an environmentally friendly choice. Their long lifespan and energy-saving properties also contribute to sustainability efforts.

Applications of PC Hollow Sheets

1. Roofing and Skylights

PC hollow sheets are widely used for roofing and skylight applications due to their excellent light transmission and thermal insulation properties. They allow natural light to enter while providing protection from the elements, making them ideal for residential, commercial, and industrial buildings.

2. Greenhouses

The agricultural industry benefits greatly from the use of PC hollow sheets in greenhouse construction. Their transparency and UV protection create an optimal growing environment by allowing sufficient sunlight while shielding plants from harmful UV rays.

3. Canopies and Awnings

Canopies and awnings made from PC hollow sheets offer durability and weather resistance. These structures provide shade and shelter while enhancing the aesthetic appeal of buildings.

4. Interior Partitions

In modern office spaces and homes, PC hollow sheets are used to create stylish and functional interior partitions. Their lightweight and transparent nature make them perfect for dividing spaces without obstructing light flow.

5. Advertising and Signage

Due to their excellent clarity and ability to withstand harsh weather conditions, PC hollow sheets are commonly used in outdoor advertising and signage. They provide a clear, durable surface for displaying graphics and messages.

6. Industrial Glazing

PC hollow sheets are employed in industrial settings for protective glazing. Their impact resistance and durability make them suitable for machinery guards, safety barriers, and other protective applications.

7. DIY Projects

Homeowners and hobbyists also use PC hollow sheets for various DIY projects. From creating garden sheds to crafting custom furniture, these versatile sheets are a favorite for creative and practical applications.

Installation and Maintenance Tips

1. Cutting and Handling

When cutting PC hollow sheets, it is essential to use appropriate tools to ensure clean, precise cuts. Protective gear should be worn to prevent injuries from sharp edges.

2. Cleaning

Regular cleaning with mild soap and water is recommended to maintain the clarity and appearance of PC hollow sheets. Abrasive cleaners and tools should be avoided to prevent scratching.

3. Sealing Edges

To enhance the thermal insulation properties and prevent moisture ingress, sealing the edges of PC hollow sheets is crucial. Proper sealing also prolongs the lifespan of the sheets by protecting them from environmental elements.

4. Support Structures

Ensuring that support structures are adequately designed and installed is essential for the stability and performance of PC hollow sheet installations. Proper spacing and secure fixing methods should be employed to prevent sagging or displacement.

Conclusion

PC hollow sheets offer a combination of durability, versatility, and aesthetic appeal that makes them an exceptional choice for a wide range of applications. Whether for construction, design, or industrial purposes, these sheets provide practical and cost-effective solutions. Their strength, lightweight nature, and excellent thermal insulation properties make them a valuable addition to any project. By choosing PC hollow sheets, builders and designers can achieve both functional and creative goals while contributing to sustainability and energy efficiency.

As technology continues to advance, the applications and benefits of Pc sheet Manufacturers are likely to expand even further, cementing their place as a crucial material in modern construction and design.

Frequently Asked Questions (FAQs):

-

What makes Singhal Industries PC Hollow Sheets a preferred choice for construction and design projects?

Singhal Industries PC Hollow Sheets are crafted from high-quality polycarbonate resin, offering exceptional strength, durability, and transparency. Their lightweight nature, combined with excellent thermal insulation and UV protection, makes them an ideal choice for a wide range of applications, including roofing, skylights, and greenhouses. With Singhal Industries' commitment to quality and innovation, our PC Hollow Sheets ensure long-lasting performance and aesthetic appeal for any project. -

How do Singhal Industries PC Hollow Sheets contribute to energy efficiency and sustainability?

Singhal Industries PC Hollow Sheets feature a hollow structure that provides superior thermal insulation, helping to maintain consistent indoor temperatures and reduce energy consumption for heating and cooling. Additionally, our PC Hollow Sheets are recyclable, supporting sustainable practices and minimizing environmental impact. By choosing Singhal Industries, you can achieve both energy efficiency and sustainability in your construction and design projects. -

What customization and support options does Singhal Industries offer for PC Hollow Sheets?

At Singhal Industries, we provide a range of customization options to meet the specific needs of our clients. Our PC Hollow Sheets are available in various sizes, colors, and transparency levels, allowing for tailored solutions that match your design and functional requirements. Our expert team is also available to offer technical guidance and support throughout the installation process, ensuring that you achieve the best results with our high-quality PC Hollow Sheets.