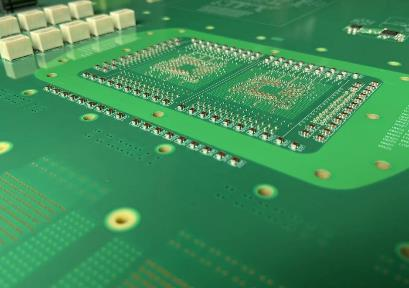

High-Performance ATE Board Assembly and ATE Printed Circuit Boards for Complex Testing Applications

When it comes to Automated Test Equipment (ATE), having a reliable, high-performance PCB is essential to ensuring the accuracy and efficiency of testing in a wide range of industries.

XPCB specializes in delivering advanced ATE board assemblies and ATE printed circuit boards (PCBs) that are engineered to meet the most demanding test environments. Whether you are testing semiconductor devices, automotive electronics, medical devices, or aerospace components, our cutting-edge PCB solutions are designed to exceed your expectations.

Advanced Technologies for Optimal Performance

XPCB’s ATE printed circuit boards stand out due to our advanced fabrication capabilities. We understand the complexities involved in ATE applications and provide solutions that ensure the highest performance in even the most challenging environments. Our state-of-the-art technologies include:

- POFV (Plated Over Filled Via): This technology enhances signal integrity and thermal management, particularly in high-power ATE applications. It ensures that the PCB can handle the stresses of demanding test environments without compromising reliability.

- Back Drilling: By eliminating stub lengths, back drilling optimizes signal integrity, especially in high-speed designs. This is crucial in ATE applications where signal accuracy and speed are paramount.

- HDI (High-Density Interconnect): With the ability to fabricate HDI on any layer, we enable complex routing and miniaturization for space-constrained designs. This capability is especially important in testing applications where high density and small form factors are necessary.

- Fine Pitch and Trace Capabilities: Our ATE PCBs support fine-pitch components and intricate trace routing, which results in higher-density designs without sacrificing performance. This ensures the most efficient and compact designs for testing.

- 40:1 Aspect Ratio: Our high aspect ratio capabilities allow for smaller vias and denser circuitry, making it possible to create more advanced ATE designs with enhanced capabilities.

Tailored Solutions for Diverse Industries

XPCB’s ATE PCBs are designed to meet the specific needs of various industries, each with its own set of requirements for testing. These include:

- Semiconductor Testing: We provide high-speed, high-density ATE board assemblies for wafer testing, chip packaging, and final product testing, ensuring accurate results and reliability.

- Automotive Electronics: Our robust ATE PCBs are ideal for testing ECUs, sensors, and other critical automotive components, meeting the rigorous standards of the automotive industry.

- Medical Devices: XPCB delivers precise, biocompatible ATE PCBs for testing medical devices, adhering to the stringent quality and safety standards of the healthcare sector.

- Aerospace and Defense: We provide high-reliability ATE board assemblies that are designed to withstand harsh environments and meet the demanding specifications of aerospace and defense testing.

Rapid Prototyping and Expert Engineering Support

In addition to our advanced manufacturing technologies, XPCB offers rapid prototyping services to accelerate your development cycles. Our expert engineering team provides Design for Manufacturability (DFM) feedback to ensure that your ATE printed circuit board designs are optimized for production, quality, and cost-effectiveness.

Whether you need quick-turn prototyping or flexible volume production, XPCB is equipped to meet your requirements and deliver the high-performance ATE board assemblies and ATE PCBs your applications demand.

XPCB stands at the forefront of providing specialized ATE PCBs engineered for superior performance and reliability. With our industry-leading technologies, expert support, and tailored solutions, we are committed to helping you succeed in even the most demanding testing environments.