Polyphenylene Sulfide Market at the Forefront of Innovation

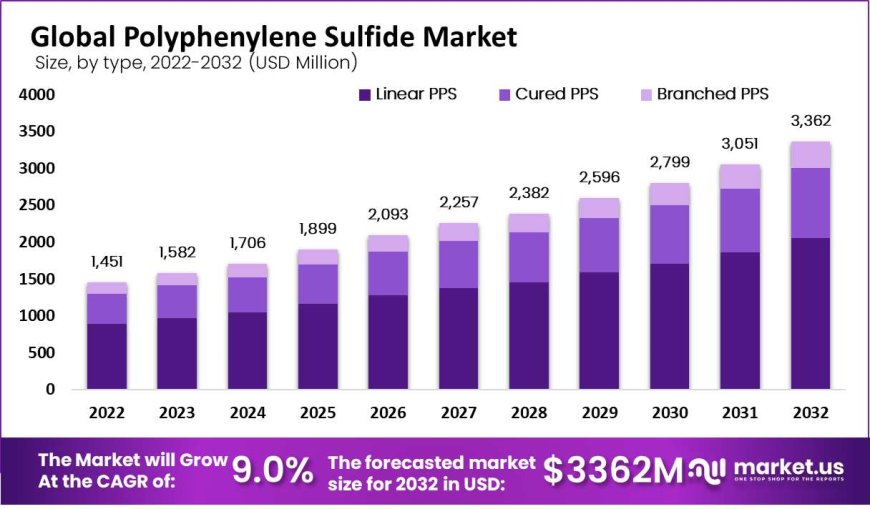

In 2022, the global polyphenylene sulfide market accounted for USD 1451 million and is expected to reach USD 3362 million in 2032. This market is estimated to register a CAGR of 9.0% between 2023 and 2032. The global polyphenylene sulfide (PPS) market for this particular type of engineering plastic, including its production, sales, and consumption worldwide.

Market Overview

The Polyphenylene Sulfide (PPS) market is a thriving segment within the polymer industry, characterized by the unique properties of PPS resin. PPS is a high-performance thermoplastic known for its exceptional resistance to heat, chemicals, and corrosion. It finds extensive use in various industries, including automotive, electrical and electronics, industrial, and aerospace, due to its ability to withstand high temperatures and harsh environments. The PPS market benefits from the increasing demand for lightweight and durable materials, particularly in automotive components, where it contributes to fuel efficiency and reduced emissions. Additionally, PPS's chemical resistance makes it a preferred choice for applications involving exposure to aggressive substances. While the market is poised for growth, challenges such as production costs and recycling processes require ongoing innovation to maintain its competitiveness and sustainability in the ever-evolving landscape of advanced materials.

In 2022, the global polyphenylene sulfide market accounted for USD 1451 million and is expected to reach USD 3362 million in 2032. This market is estimated to register a CAGR of 9.0% between 2023 and 2032. The global polyphenylene sulfide (PPS) market for this particular type of engineering plastic, including its production, sales, and consumption worldwide.

Key Player

-

Market Key Players

- Toray Industries Inc.

- DIC CORPORATION

- Solvay S.A.

- Lion Idemitsu Composites Co. Ltd

- Polyplastics Co. Ltd.

- Tosoh Corporation

- SK chemicals

- Chengdu Letian Plastics Co. Ltd.

- Celanese Corporation

- TEIJIN LIMITED

- SABIC

- Zhejiang NHU Co. Ltd.

- LG Chem

- RTP Company

- Ensinger

- Other Key Players

Download a sample report @ https://market.us/report/polyphenylene-sulfide-market/request-sample/

Key Market Segments

Based on Type

- Linear PPS

- Cured PPS

- Branched PPS

Based on Application

- Automotive

- Electrical & Electronics

- Filter Bags

- Aerospace

- Industrial

- Coatings

- Other Applications

Demand:

The demand for Polyphenylene Sulfide (PPS) in the global market is steadily increasing, driven by its exceptional properties and diverse applications across various industries. PPS, known for its high-temperature resistance, excellent chemical stability, and superior mechanical properties, is in high demand, particularly in the automotive sector, where it is used in components that require heat resistance, such as under-the-hood parts, electrical connectors, and fuel systems. Additionally, the electrical and electronics industry relies on PPS for its insulating properties and resistance to electrical stress, making it a preferred choice for connectors, circuit boards, and various electronic components. In the industrial sector, PPS is valued for its chemical resistance and durability in demanding environments, while the aerospace industry benefits from its lightweight and high-performance characteristics. As sustainability becomes a global priority, PPS's recyclability and potential for lightweighting continue to drive its demand in various applications, positioning it as a critical material in addressing the evolving needs of modern industries.

Market Challenges

The Polyphenylene Sulfide (PPS) market faces several noteworthy challenges that affect its widespread adoption and growth. Firstly, the production of high-quality PPS resin is a complex and costly process, which can lead to higher material costs and limit its competitiveness compared to other polymers. Secondly, while PPS offers excellent heat resistance, it can be relatively brittle, which can be a limitation in applications requiring high impact strength. Thirdly, recycling PPS can be challenging due to its chemical stability, potentially leading to concerns about environmental sustainability and disposal. Moreover, competition from alternative materials in certain applications, such as thermoplastics and thermosetting resins, poses a challenge for PPS in terms of market share. Lastly, fluctuations in raw material prices and supply chain disruptions can impact the overall cost of PPS production. Addressing these challenges requires ongoing research and development efforts to improve PPS properties, reduce production costs, and find sustainable recycling solutions, ensuring its continued relevance and competitiveness in various industries.

Market Opportunities

The Polyphenylene Sulfide (PPS) market presents promising opportunities driven by its unique properties and adaptability to diverse industries. Firstly, in the automotive sector, the demand for lightweight and high-performance materials is on the rise, and PPS is well-positioned to meet these needs, contributing to fuel efficiency and reduced emissions. Secondly, the electrical and electronics industry continues to grow, and PPS's excellent electrical insulating properties make it a preferred choice for various components, including connectors, sockets, and insulators. Thirdly, the increasing focus on sustainability and environmental responsibility aligns with PPS's recyclability, making it an attractive option for manufacturers looking to reduce their environmental footprint. Additionally, PPS's chemical resistance and durability find applications in the industrial sector, offering opportunities for corrosion-resistant and long-lasting products. Furthermore, PPS's adaptability to additive manufacturing processes opens doors to innovative and complex design possibilities. As industries evolve, PPS remains poised to address emerging challenges and opportunities, making it a versatile and valuable material in the ever-changing landscape of advanced polymers.

Key Benefits:

The Polyphenylene Sulfide (PPS) market offers a multitude of key benefits that distinguish it as a highly sought-after material. Firstly, PPS's exceptional heat resistance allows it to withstand elevated temperatures, making it ideal for applications in automotive under-the-hood components, electrical connectors, and other heat-intensive environments. Secondly, its superior chemical resistance ensures longevity and reliability, particularly in industries dealing with aggressive chemicals and corrosive substances. Thirdly, PPS's excellent electrical insulating properties make it indispensable in the electrical and electronics industry, where it enhances the performance and safety of various components. Additionally, its lightweight nature contributes to fuel efficiency and reduced emissions in automotive applications, aligning with sustainability goals. Furthermore, PPS's dimensional stability, mechanical strength, and resistance to creep and fatigue make it a dependable choice for a wide range of demanding applications. These combined advantages position PPS as a critical material in addressing contemporary industry requirements for durability, efficiency, and environmental responsibility.

Top Five Trends

The Polyphenylene Sulfide (PPS) market is experiencing several prominent trends that are reshaping its landscape and impact. Firstly, there's a growing emphasis on lightweighting in the automotive industry, with PPS being increasingly used in place of metal components to improve fuel efficiency and reduce emissions. Secondly, the electrical and electronics sector is witnessing a surge in demand for PPS due to its exceptional electrical insulating properties, essential for miniaturized electronic devices and connectors. Thirdly, sustainability and environmental responsibility are driving the trend towards recyclable materials, positioning PPS favorably for its recyclability and potential for a circular economy. Additionally, the adoption of additive manufacturing technologies is expanding the design possibilities for PPS, enabling complex and customized parts in various industries. Lastly, innovations in PPS formulations and processing techniques are broadening its applications, enhancing its mechanical properties, and further solidifying its position as a high-performance polymer in an evolving market. These trends collectively underscore PPS's adaptability, versatility, and continued relevance in addressing industry demands and emerging challenges.

Conclusion:

In conclusion, the Polyphenylene Sulfide (PPS) market stands as a testament to the evolution of high-performance polymers in addressing the dynamic needs of modern industries. With its exceptional heat resistance, chemical stability, and electrical insulating properties, PPS has found its place in automotive, electrical, electronics, and industrial applications, contributing to efficiency, durability, and sustainability. While challenges such as production costs and recycling processes persist, ongoing research and development efforts are expanding the boundaries of PPS, enhancing its properties, and promoting sustainability through recyclability. As industries increasingly prioritize lightweighting, electrical efficiency, and environmental responsibility, PPS remains a versatile and indispensable material, bridging the gap between innovation and practicality. Its continued evolution exemplifies the critical role of advanced polymers in advancing technology, enhancing performance, and meeting the evolving demands of a rapidly changing world.

Contact us

Global Business Development Team: Market.us

Market.us (Powered By Prudor Pvt. Ltd. )

Send Email:inquiry@market.us

Address: 420 Lexington Avenue, Suite 300 New York City, NY 10170, United States

Tel: +1 718 618 4351, +91 78878 22626

Website:https://market.us/