Enhancing Interior Aesthetics with WPC Wall Panels: A Comprehensive Guide

In the realm of interior design and construction, the choice of wall panels plays a crucial role in defining the aesthetics, durability, and sustainability of a space. Wood Plastic Composite (WPC) wall panels have emerged as a popular choice for both residential and commercial applications due to their versatility, low maintenance requirements, and eco-friendly characteristics. This blog aims to explore the myriad benefits, applications, and installation processes of Wpc panels Suppliers, shedding light on why they are a preferred choice for enhancing interior spaces.

Understanding WPC Wall Panels

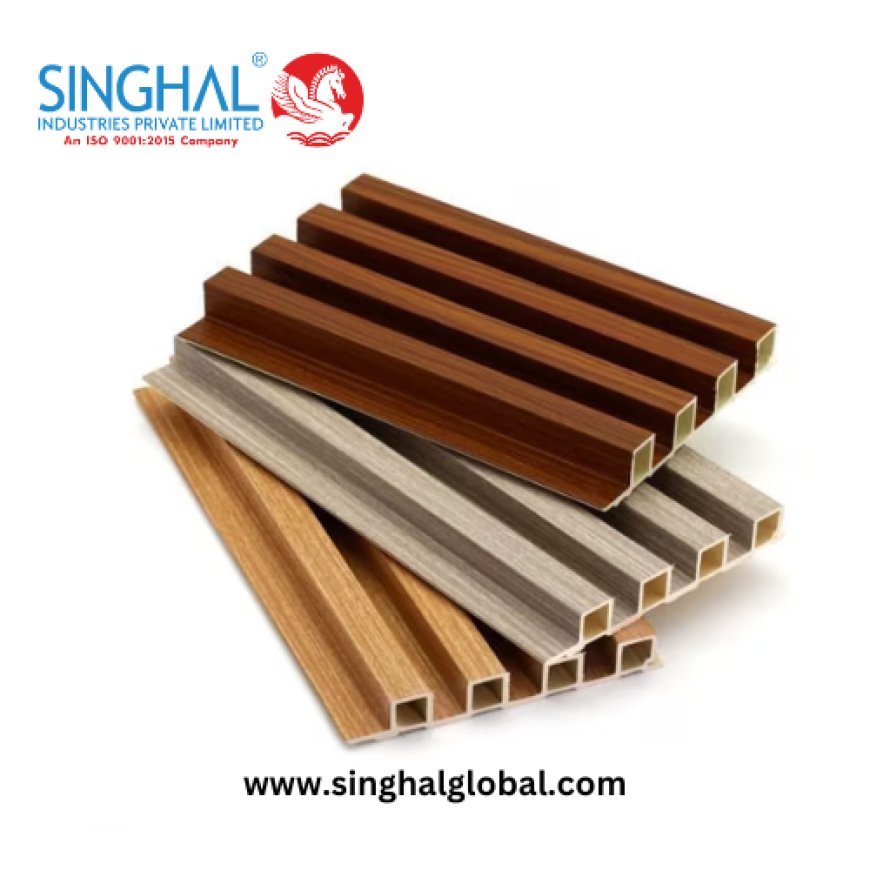

Wood Plastic Composite (WPC) wall panels are innovative building materials that combine wood fibers or flour with thermoplastics to create a composite material with the appearance and texture of natural wood. Wpc pannel Manufacturers offer the warmth and beauty of wood without the drawbacks of traditional wooden panels, such as susceptibility to moisture, rot, and insect damage. These panels are available in a variety of colors, textures, and finishes, allowing for endless design possibilities in interior spaces.

Benefits of WPC Wall Panels

The popularity of WPC wall panels can be attributed to several key benefits:

-

Durability: WPC wall panels are highly durable and resistant to moisture, rot, and decay, making them suitable for use in high-moisture environments such as bathrooms, kitchens, and basements. Unlike traditional wooden panels, WPC panels do not warp, crack, or splinter, ensuring long-term performance and aesthetics.

-

Low Maintenance: WPC wall panels require minimal maintenance compared to wood or other materials. They are easy to clean with just soap and water, eliminating the need for specialized cleaners or treatments. Additionally, WPC panels do not require painting, staining, or sealing, saving time and effort in maintenance tasks.

-

Versatility: WPC wall panels offer versatility in design and installation, allowing for creative expression in interior spaces. They can be easily cut, drilled, and shaped to fit any wall or surface, making them suitable for both straight and curved applications. Additionally, WPC panels can be painted or stained to match any decor style or color scheme.

-

Environmental Sustainability: WPC wall panels are an eco-friendly alternative to traditional wood panels. They are made from recycled materials, such as wood fibers and plastic waste, reducing the demand for virgin materials and minimizing environmental impact. Furthermore, WPC panels are recyclable at the end of their lifespan, contributing to a circular economy and sustainable resource management.

-

Insulation Properties: WPC wall panels offer thermal and acoustic insulation properties, helping to regulate indoor temperature and reduce noise transmission. This makes them an ideal choice for improving comfort and energy efficiency in residential and commercial buildings.

Applications of WPC Wall Panels

WPC wall panels find applications in various interior spaces, including:

-

Residential Interiors: In residential settings, WPC wall panels are used to enhance the aesthetics of living rooms, bedrooms, and dining areas. They can be installed as accent walls, feature panels, or wainscoting to add texture, warmth, and visual interest to the space.

-

Commercial Spaces: WPC wall panels are commonly used in commercial spaces such as offices, hotels, restaurants, and retail stores. They create a welcoming and stylish environment for customers and employees while offering durability and easy maintenance for busy environments.

-

Public Facilities: Public facilities such as schools, hospitals, and community centers benefit from the use of WPC wall panels. These panels provide a hygienic and aesthetically pleasing solution for walls and partitions, enhancing the overall ambiance and functionality of the space.

-

Wet Areas: WPC wall panels are ideal for wet areas such as bathrooms, kitchens, and spas due to their moisture-resistant properties. They provide a durable and waterproof surface that withstands exposure to water, steam, and humidity without compromising aesthetics or performance.

Installation of WPC Wall Panels

The installation of WPC wall panels is straightforward and can be done by DIY enthusiasts or professional contractors. Here's a general overview of the installation process:

-

Surface Preparation: Ensure that the wall surface is clean, dry, and free from dust, grease, and debris. Remove any existing trim or fixtures that may interfere with the installation of the panels.

-

Measurement and Cutting: Measure the wall area and cut the WPC panels to size using a saw or cutting tool. Leave a small gap around the edges of the panels to allow for expansion and contraction.

-

Adhesive Application: Apply a high-quality construction adhesive to the back of the WPC panels using a caulking gun or adhesive spreader. Ensure that the adhesive is evenly distributed across the surface of the panel.

-

Panel Installation: Press the WPC panels firmly onto the wall surface, starting from one corner and working your way across the wall. Use a level to ensure that the panels are installed straight and plumb.

-

Finishing Touches: Once all the panels are installed, trim any excess material from the edges using a saw or utility knife. Install trim pieces, corner caps, or molding to cover any gaps and create a seamless finish.

-

Sealing and Caulking: Seal any gaps between the panels and the wall surface using a silicone caulk or sealant. This helps prevent water infiltration and ensures a watertight seal around the edges of the panels.

-

Final Inspection: Conduct a final inspection to ensure that the panels are securely installed and properly aligned. Make any necessary adjustments or touch-ups to achieve the desired result.

Environmental Impact and Sustainability

WPC wall panels offer several environmental benefits compared to traditional wood panels:

-

Recycled Materials: WPC panels are made from recycled materials, including wood fibers and plastic waste, reducing the demand for virgin materials and minimizing waste generation.

-

Energy Efficiency: The production of WPC panels consumes less energy compared to the production of traditional wood panels, contributing to energy efficiency and reduced carbon emissions.

-

Longevity and Durability: WPC panels have a long lifespan and require minimal maintenance, resulting in fewer replacements and reduced waste generation over time.

Future Trends and Innovations

The future of WPC wall panels is characterized by ongoing innovation and technological advancements:

-

Advanced Materials: Research and development efforts are focused on developing advanced WPC materials with enhanced properties such as fire resistance, UV stability, and antimicrobial properties.

-

Digital Printing Technology: Digital printing technology is being utilized to create realistic wood grain patterns and textures on WPC panels, offering greater design flexibility and customization options.

-

Smart Integration: Integration of smart technologies such as LED lighting, sound systems, and touch controls into WPC wall panels is being explored to create interactive and multifunctional interior spaces.

Conclusion

WPC wall panels offer a versatile, durable, and environmentally sustainable solution for enhancing interior spaces. Their numerous benefits, including durability, low maintenance requirements, and eco-friendliness, make them a preferred choice for residential, commercial, and public applications. As technology and innovation continue to advance, the future of WPC wall panels looks promising, with ongoing efforts to enhance their performance, aesthetics, and functionality. By WPC pannel price the benefits, applications, and installation processes of WPC wall panels, homeowners, architects, and designers can make informed decisions that elevate the beauty and functionality of interior spaces.

Frequently Asked Questions (FAQs):

1. How does Singhal Industries ensure the quality and durability of their WPC wall panels?

Singhal Industries is committed to delivering high-quality WPC wall panels that meet stringent standards of durability and performance. Our panels are manufactured using advanced processes and premium-grade materials to ensure long-lasting durability and resistance to wear, moisture, and environmental factors. Additionally, we conduct rigorous quality control checks at every stage of production to maintain consistency and excellence in our products.

2. What design options are available for WPC wall panels from Singhal Industries?

Singhal Industries offers a wide range of design options for WPC wall panels to suit diverse aesthetic preferences and interior styles. Our panels come in various colors, textures, and finishes, including wood grain patterns, stone effects, and contemporary designs. Whether you prefer a classic, rustic look or a modern, sleek finish, we have options to complement any decor theme and enhance the visual appeal of your space.

3. How does Singhal Industries contribute to sustainability through their production of WPC wall panels?

At Singhal Industries, we are committed to environmental sustainability and responsible manufacturing practices. Our WPC wall panels are made from recycled materials, including wood fibers and plastic waste, reducing the demand for virgin resources and minimizing waste generation. Additionally, our production processes prioritize energy efficiency and resource conservation, further reducing our environmental footprint. By choosing Singhal Industries' WPC wall panels, customers can contribute to a greener future while enjoying high-quality, stylish interior solutions.