The Ultimate Guide to Choosing the Best Paver Block Making Machine

The Ultimate Guide to Choosing the Best Paver Block Making Machine

Paver blocks have become an increasingly popular choice for driveways, walkways, patios and other outdoor surfaces. Their durability, aesthetic appeal, and ease of installation make them a preferred option for both residential and commercial projects. However, the quality and consistency of paver blocks depend heavily on the machine used to produce them. This guide will help you navigate the process of selecting the ideal paver block making machine for your needs.

Understanding Paver Block Making Machines

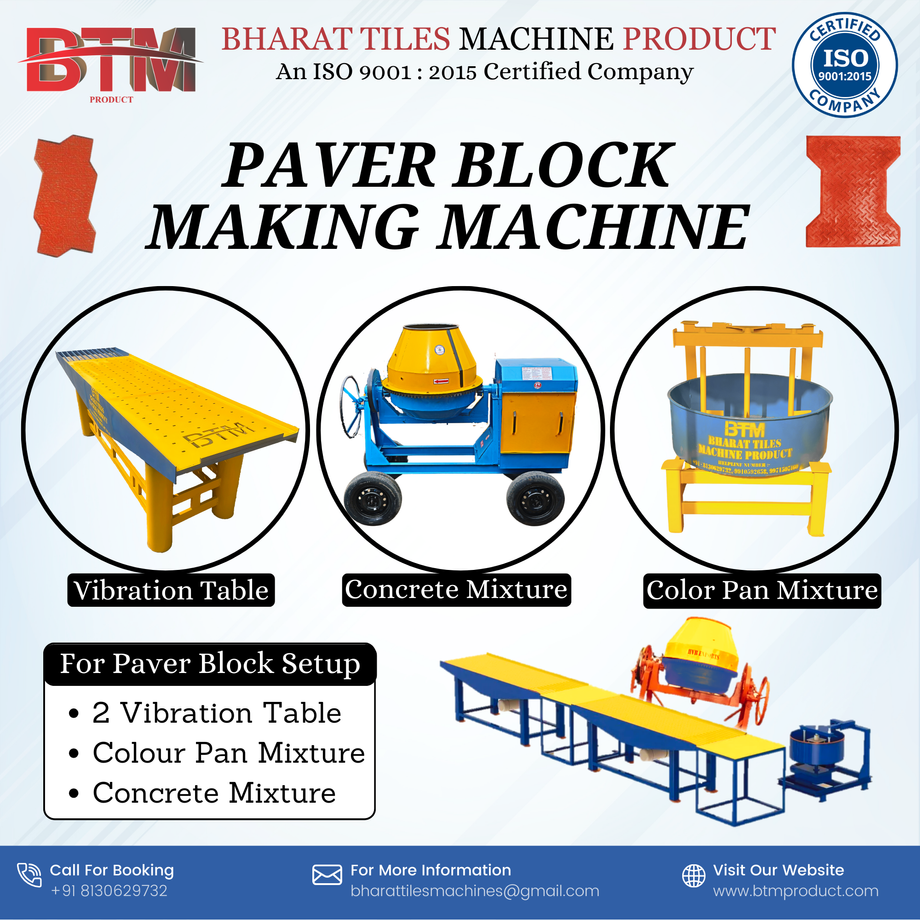

A paver block making machine is specialized equipment designed to manufacture concrete paver blocks efficiently and consistently. These machines compress a mixture of cement, sand, aggregates, and water into molds to create blocks of various shapes, sizes, and designs. The right machine can significantly boost productivity, improve product quality, and reduce labor costs.

Key Factors to Consider

1. Production Capacity

One of the most critical factors in choosing a paver block making machine is its production capacity. Consider your current and projected future needs. Machines can range from small units producing a few hundred blocks per day to large-scale operations capable of manufacturing thousands of blocks in a single shift.

BTM Product offers a range of machines to suit different production requirements, from small-scale to industrial-level manufacturing.

2. Block Variety

Different projects may require various types of paver blocks. Look for a machine that can produce a wide range of block shapes, sizes, and designs. Versatility in production can help you cater to diverse customer needs and expand your market reach.

3. Automation Level

Paver block making machines come with varying degrees of automation. While fully automated systems require a higher initial investment, they can significantly reduce labor costs and increase efficiency in the long run. Semi-automated options offer a balance between cost and productivity.

4. Quality of Output

The consistency and quality of the paver blocks are paramount. Look for machines that produce uniform blocks with precise dimensions and smooth finishes. High-quality output not only satisfies customers but also reduces waste and rework.

5. Durability and Maintenance

Investing in a durable machine can save you money and headaches in the long term. Consider the machine's build quality, the materials used in its construction, and its reputation for reliability. Additionally, factor in the ease of maintenance and availability of spare parts.

6. Energy Efficiency

With rising energy costs, the power consumption of your paver block making machine can significantly impact your operational expenses. Look for energy-efficient models that can help reduce your carbon footprint and operating costs.

7. Safety Features

Prioritize machines with robust safety features to protect your workers and comply with industry regulations. Look for emergency stop buttons, safety guards, and other protective mechanisms.

8. Ease of Operation

User-friendly controls and intuitive interfaces can reduce training time and minimize errors. Consider the skill level of your workforce when selecting a machine.

Types of Paver Block Making Machines

1. Stationary Machines

These are fixed installations suitable for large-scale production. They offer high output and consistency but require a dedicated production area.

2. Mobile Machines

Ideal for on-site production, these machines can be moved to different locations. They're particularly useful for remote projects or when transportation of finished blocks is challenging.

3. Hydraulic Machines

Hydraulic systems provide consistent pressure, resulting in high-quality blocks. They're often more durable and suitable for heavy-duty production.

4. Mechanical Machines

These machines use mechanical force for block formation. While they may be less expensive, they might not offer the same level of consistency as hydraulic systems.

5. Egg-Laying Machines

These specialized machines produce blocks directly on the curing area, eliminating the need for additional handling of fresh blocks.

Cost Considerations

When budgeting for a paver block making machine, consider not just the initial purchase price but also:

- Installation costs

- Training expenses

- Ongoing maintenance and repair costs

- Energy consumption

- Potential labor savings

- Projected return on investment

BTM Product offers competitive pricing across its range of paver block making machines, ensuring options for various budget levels.

Our Other Machines

interlocking tiles making machine

Technology and Innovation

The paver block industry is continually evolving, with new technologies enhancing production processes. Look for machines that incorporate the latest innovations:

- Computer-controlled systems for precise mix ratios and block formation

- Advanced vibration technology for better compaction

- Color mixing systems for creating multi-colored blocks

- Sensors and diagnostics for predictive maintenance

Environmental Considerations

As sustainability becomes increasingly important, consider machines that support eco-friendly production methods:

- Ability to use recycled materials in the mix

- Water recycling systems

- Energy-efficient motors and hydraulics

- Dust suppression mechanisms

BTM Product is committed to sustainability, offering machines designed with environmental considerations in mind.

After-Sales Support

The support you receive after purchasing your paver block making machine can be as important as the machine itself. Consider:

- Warranty terms and duration

- Availability of technical support

- Speed of response for repairs and maintenance

- Training programs for operators

- Availability of spare parts

BTM Product prides itself on comprehensive after-sales support, ensuring customers get the most out of their investment.

Case Studies and Customer Reviews

Before making a final decision, research case studies and customer reviews of the machines you're considering. Look for feedback on:

- Actual production rates compared to stated capacities

- Reliability and downtime experiences

- Quality of blocks produced

- Customer service experiences

- Return on investment timelines

Many satisfied customers have shared their positive experiences with BTM Product's paver block making machines, citing reliability, efficiency, and excellent support.

Customization Options

Every production setup is unique. Look for manufacturers willing to customize their machines to meet your specific requirements. This might include:

- Custom mold designs

- Integration with existing production lines

- Specific automation requirements

- Special color mixing systems

BTM Product offers customization services to ensure their machines fit seamlessly into your production process.

Future-Proofing Your Investment

When selecting a paver block making machine, consider your future needs:

- Scalability: Can the machine's output be increased if needed?

- Upgradability: Can new features or technologies be added later?

- Versatility: Can the machine adapt to produce new block designs or use different materials?

Choosing a machine that can grow with your business can save you from costly replacements down the line.

Making the Final Decision

After considering all these factors, it's time to make your decision. Here's a final checklist:

1. Does the machine meet your current and projected production needs?

2. Is it within your budget, considering both initial and long-term costs?

3. Does it offer the quality and consistency required for your market?

4. Is the manufacturer reputable with good after-sales support?

5. Does the machine align with your sustainability goals?

6. Can it adapt to future market trends and production needs?

Some Blogs

Automatic Fly Ash Brick Making Machine at the Best Price

Get the Best Fly Ash Brick Making Machine in India

Conclusion

Selecting the right paver block making machine is a crucial decision that can significantly impact your business's success. By carefully considering factors such as production capacity, block variety, automation level, and long-term costs, you can make an informed choice that aligns with your business goals and market demands.

Remember that the cheapest option isn't always the most cost-effective in the long run. Invest in quality, efficiency, and reliability to ensure your paver block production thrives.

BTM Product offers a comprehensive range of paver block making machines designed to meet diverse needs and budgets. With a commitment to quality, innovation, and customer support, BTM Product stands ready to help you find the perfect machine for your paver block production journey.

Whether you're just starting in the industry or looking to upgrade your existing setup, take the time to thoroughly research and compare your options. The right paver block making machine can be the foundation of a successful and profitable business for years to come.