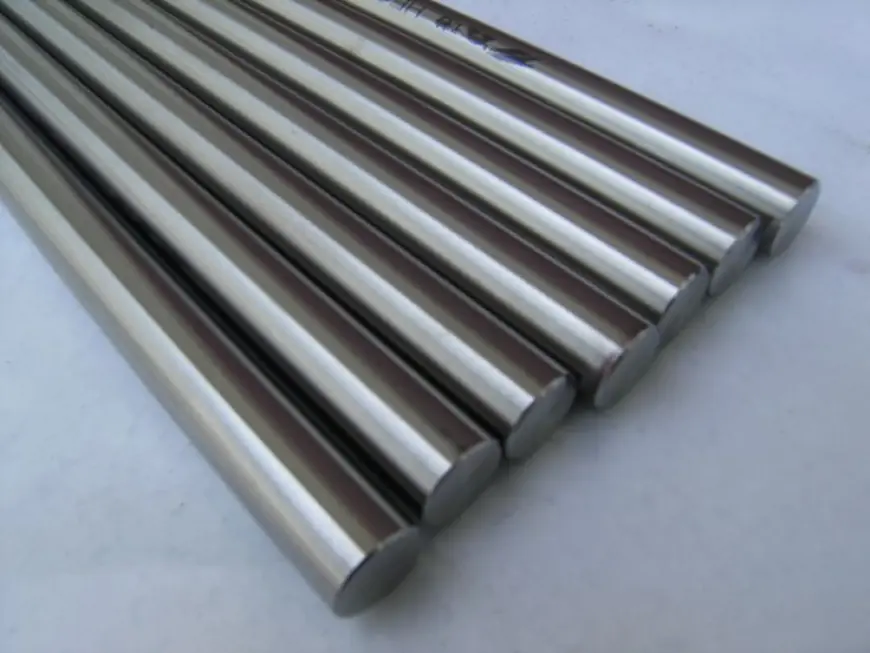

An Overview of Titanium Grade 5 Round Bar

Explore Titanium Grade 5 round bar, known for their strength, corrosion resistance, and versatility. Perfect for high-performance applications in various industries.

Titanium Grade 5, known as Ti-6Al-4V, is one of the most widely used titanium alloys. This alloy consists of 90% titanium, 6% aluminium, and 4% vanadium, which gives it a unique combination of high strength, low weight, and excellent corrosion resistance. Titanium Grade 5 Round Bar is often utilized in industries that require materials to withstand extreme conditions, such as aerospace, medical, and marine applications.

Key Properties of Titanium Grade 5 Round Bar

1. High Strength-to-Weight Ratio: Titanium Grade 5 has an impressive strength-to-weight ratio, making it ideal for applications where both high strength and lightweight properties are essential. It offers high tensile strength (approximately 1300 MPa or 190 ksi), which is critical for components in the aerospace and automotive industries.

2. Excellent Corrosion Resistance: Titanium Grade 5 exhibits excellent resistance to corrosion in many aggressive environments, including seawater, chlorine, and strong acids. The alloy's natural oxide layer protects against corrosion, making it highly suitable for harsh environments like marine, chemical processing, and power generation industries.

3. High-Temperature Stability: Titanium Grade 5 Round Bar performs well under elevated temperatures, maintaining its mechanical properties even in environments up to 400-500°C (752-932°F). This high-temperature stability is crucial for aerospace and turbine applications, where components are exposed to high-heat environments.

4. Biocompatibility: Titanium Grade 5 is biocompatible, which means it does not cause adverse reactions when in contact with living tissue. This property makes it widely used for surgical implants, dental devices, and medical instruments, offering a safe and long-lasting solution for medical applications.

Applications of Titanium Grade 5 Round Bar

1. Aerospace Industry: Titanium Grade 5 is one of the most commonly used materials in aerospace engineering. Its strength, lightweight nature, and corrosion resistance make it an ideal choice for aircraft components, including turbine blades, engine parts, structural elements, and fasteners. The alloy's ability to withstand high temperatures and pressures makes it essential for jet engines and other high-performance aerospace applications.

2. Medical Field: Due to its biocompatibility and strength, Titanium Grade 5 Round Bars are extensively used in medical implants such as hip replacements, dental implants, and bone plates. The alloy's ability to resist corrosion in the human body ensures the longevity and safety of medical devices.

3. Marine Industry: Titanium Grade 5 Round Bars' high corrosion resistance makes them suitable for use in seawater and other aggressive marine environments. They are commonly used in offshore drilling rigs, submarine components, and shipbuilding.

4. Chemical Processing and Power Generation: Titanium Grade 5 is used in chemical and power plants' heat exchangers, pressure vessels, and reactor components. The material's corrosion resistance allows it to perform well in environments involving acids, chlorine, and high-pressure steam.

Manufacturing of Titanium Grade 5 Round Bar

Titanium Grade 5 Round Bars are manufactured using several processes, including:

Forging: The titanium alloy is heated and shaped into billets before being rolled into round bars. Forging enhances the material's mechanical properties by aligning the grain structure.

Rolling: After forging, the billets are hot rolled to achieve the desired diameter and shape. This process also refines the material's surface finish and dimensional accuracy.

Heat Treatment: Heat treatment processes such as annealing and solution treatment are applied to further enhance strength and mechanical properties.

Machining: CNC machines cut, shape, and finish the round bars to precise specifications.

Advantages of Titanium Grade 5 Round Bar

1. Durability and Longevity: Titanium Grade 5 Round Bars provide exceptional durability and resistance to wear and tear, even in the most demanding environments. This longevity reduces maintenance costs and ensures reliable performance in critical applications.

2. Reduced Weight without Sacrificing Strength: Titanium Grade 5 offers an optimal balance between strength and weight, making it suitable for weight-sensitive applications like aerospace and automotive components.

3. Versatility: Titanium Grade 5 is highly versatile, and its properties can be tailored through various heat treatments and processing methods to meet the specific needs of different industries.

rautsakshi567

rautsakshi567