Additive Manufacturing Market Dynamics: A Closer Look

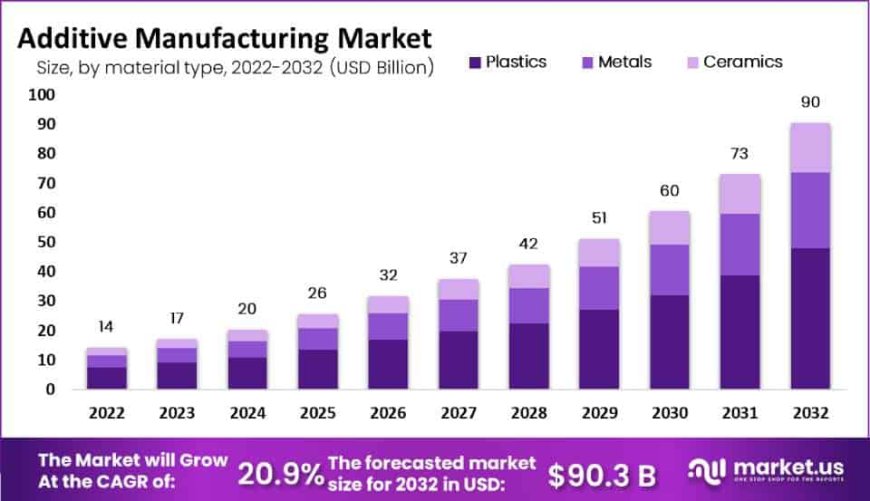

In 2022, the Global Additive Manufacturing Market was valued at US$ 14.2 billion; this market is estimated to register at the highest CAGR of 20.9% during the forecast period of 2023 to 2032.

Market Overview

The Additive Manufacturing Market, also known as 3D printing, has emerged as a transformative force in the realm of manufacturing and production. It revolves around the concept of creating three-dimensional objects layer by layer, offering remarkable flexibility and versatility. This technology has disrupted traditional manufacturing processes by enabling rapid prototyping, reduced lead times, and cost-effective small-batch production. It has found applications across diverse industries, including aerospace, healthcare, automotive, and consumer goods.

The demand for Additive Manufacturing is driven by the need for highly customized, intricate, and low-volume production, making it invaluable for producing complex geometries and functional prototypes. It has the potential to reduce material wastage and environmental impact, aligning with sustainability goals.

However, challenges persist, such as material limitations, post-processing requirements, and the need for standardized processes. Quality control and intellectual property concerns remain critical issues to address.

Opportunities for the Additive Manufacturing Market continue to expand as innovations in materials and technologies progress. From metal 3D printing to bioprinting of human tissues, the scope is vast. As adoption grows, a shift towards hybrid manufacturing, combining additive and subtractive techniques, is becoming more prevalent.

The benefits are evident, including reduced production costs, on-demand manufacturing, and accessibility to complex designs. The Additive Manufacturing Market is experiencing an era of rapid evolution, and its trajectory promises to revolutionize how we create, build, and shape the future of manufacturing.

In 2022, the Global Additive Manufacturing Market was valued at US$ 14.2 billion; this market is estimated to register at the highest CAGR of 20.9% during the forecast period of 2023 to 2032.

The Main Players

-

Market Principal Participants

- SLM Solutions

- Proto Labs

- Renishaw Plc.

- Titomic Limited.

- Höganäs AB

- Ultimaker BV

- Optomec, Inc.

- ExOne

- American Additive Manufacturing LLC

- ANSYS, Inc.

- ARBURG GmbH + Co KG

- ENVISIONTEC US LLC

- EOS GmbH

- 3D Systems Inc.

- Arcam AB

- Wipro Limited

- Other Key Players

Download a sample report @ https://market.us/report/the-additive-manufacturing-market/request-sample/

Key Market Segments

Based on Material Type

- Plastics

- Metals

- Ceramics

Based on Technology

- Stereolithography (SLA)

- Fused Disposition Modelling (FDM)

- Laser Sintering (LS)

- Binder Jetting Printing

- Polyjet Printing

- Electron Beam Melting (EBM)

- Laminated Object Manufacturing (LOM)

- Others

Based on Application

- Aerospace

- Automotive

- Consumer Products

- Government and Defense

- Healthcare

- Industrial Machines

- Others

Key Drivers:

The key drivers fueling the growth of the Additive Manufacturing Market are multifold. First and foremost, the ever-increasing demand for highly customized and complex products across various industries, such as aerospace, healthcare, automotive, and engineering, is a significant driver. Additive manufacturing's ability to create intricate designs and prototypes with minimal tooling and setup is a game-changer.

Additionally, the drive for supply chain optimization and the reduction of lead times is propelling the adoption of 3D printing. This technology allows for on-demand and local manufacturing, which can reduce inventory costs and streamline production processes. Moreover, its environmental benefits, including reduced material wastage and energy efficiency, align with sustainability objectives and contribute to its growth.

Innovations in materials, such as advanced polymers, composites, and metal alloys, continue to expand the application areas for additive manufacturing. This is further boosted by the advent of multi-material and multi-process 3D printing technologies, enhancing the technology's versatility.

Lastly, the increasing adoption of Industry 4.0 and digitalization in manufacturing processes is driving the integration of 3D printing into smart factories and interconnected production lines. As a result, additive manufacturing is poised to play a pivotal role in the Fourth Industrial Revolution. These drivers collectively underscore the transformative potential and ongoing growth of the Additive Manufacturing Market.

Key Restraints

The Additive Manufacturing Market faces several key restraints that impact its widespread adoption. One of the significant challenges is the high cost associated with 3D printing equipment, materials, and software. While prices have been decreasing, the initial investment remains substantial, limiting accessibility for smaller businesses.

Another challenge is the limited range of available materials and the need for material certification in industries with stringent quality requirements like aerospace and healthcare. Scaling up production can also be a limitation due to time-consuming processes and build size constraints. Moreover, intellectual property concerns, especially in open-source 3D printing, raise questions about data security and copyright infringements.

Inconsistent quality and surface finish can be a drawback, as post-processing and additional steps are often required to meet industry standards. Additionally, regulatory and safety concerns in sectors like healthcare can hinder the adoption of 3D printing technologies. Lastly, the lack of skilled workforce and the need for adequate training and expertise remain a constraint, impacting the technology's utilization to its full potential. Addressing these restraints is essential for the broader integration of additive manufacturing into various industries.

Market Trends:

The Additive Manufacturing Market is experiencing several noteworthy trends that are reshaping the industry. One prominent trend is the expansion of 3D printing applications beyond prototyping into full-scale production across various sectors, including aerospace, automotive, healthcare, and consumer goods. In response to environmental concerns, there is a growing focus on sustainable practices, leading to the development of eco-friendly materials and processes within the additive manufacturing sphere.

Furthermore, the integration of additive manufacturing with digital twin technology is enabling real-time monitoring and optimization of printing processes, improving efficiency and reducing errors. Collaborative partnerships between major players and startups are fostering innovation and driving the adoption of advanced materials and technologies. Hybrid manufacturing, which combines additive and subtractive processes, is emerging as a viable solution for achieving higher precision and smoother surface finishes.

The healthcare industry is witnessing a surge in personalized medical devices, implants, and pharmaceuticals through 3D printing, catering to unique patient needs. Lastly, the democratization of additive manufacturing is on the rise, with a focus on making 3D printing more accessible to smaller businesses and individuals, leading to a broader adoption and exploration of its capabilities. These trends indicate the growing impact of additive manufacturing on various industries and its potential for transformative change.

Conclusion:

In conclusion, the Additive Manufacturing Market is a rapidly evolving and dynamic sector that continues to push the boundaries of traditional manufacturing processes. With its versatile applications, cost-effective production, and sustainability advantages, additive manufacturing is poised to revolutionize how we design and create products across numerous industries. As technology advances, addressing challenges like material limitations, quality control, and scalability will be crucial for its continued growth. With ongoing innovation, collaborative efforts, and increased accessibility, this market is well-positioned for sustained expansion, offering exciting opportunities and driving a profound transformation in manufacturing practices, supply chains, and product customization, shaping the future of production in an increasingly digital world.

Connect To Our Team

Global Business Development Team: Market.us

Market.us (Powered By Prudor Pvt. Ltd. )

Send Email:inquiry@market.us

Address: 420 Lexington Avenue, Suite 300 New York City, NY 10170, United States

Tel: +1 718 618 4351, +91 78878 22626

Website:https://market.us/