United Kingdom Aerospace Carbon Fibre Market: Size, Growth, and Future Prospects (2024-2032)

The aerospace carbon fibre market in the United Kingdom is set to experience significant growth over the coming years. The United Kingdom aerospace carbon fibre market size is assessed to grow at a CAGR of 8.3% between 2024 and 2032. This growth is driven by the robust expansion of the aerospace sector and an increasing focus on enhancing the sustainability of aircraft. As the demand for lightweight and fuel-efficient aircraft continues to rise, carbon fibre has emerged as a crucial material in the aerospace industry.

Market Segmentation

By Material

Pan Based

Pan-based carbon fibres are widely used in aerospace due to their high strength and stiffness. These fibres are produced from polyacrylonitrile (PAN) precursors, which provide superior mechanical properties compared to other types. In aerospace applications, Pan-based carbon fibres are essential for manufacturing structural components, contributing to weight reduction and fuel efficiency.

Pitch Based

Pitch-based carbon fibres are derived from petroleum or coal tar pitch. They offer excellent thermal and electrical conductivity, making them suitable for specific aerospace applications such as thermal management and electromagnetic interference shielding. Although they are less common than Pan-based fibres, their unique properties make them valuable in certain high-performance aerospace components.

By Type

Continuous Carbon Fibre

Continuous carbon fibres are long strands that provide superior strength and durability. In the aerospace sector, these fibres are used in the fabrication of primary and secondary structural components, including wings, fuselages, and tail sections. The continuous nature of these fibres ensures uniform load distribution and enhances the structural integrity of the aircraft.

Long Carbon Fibre

Long carbon fibres are slightly shorter than continuous fibres but still offer considerable strength and stiffness. They are often used in semi-structural components and interior applications where high performance is required but continuous fibres may not be necessary. Their adaptability makes them suitable for various aerospace applications, including panels and interior fittings.

Short Carbon Fibre

Short carbon fibres are chopped fibres that are typically used in composite materials for non-structural applications. These fibres are blended with resins to create lightweight and durable components for aircraft interiors, such as seating, overhead compartments, and other cabin elements. The use of short carbon fibres helps reduce the overall weight of the aircraft, contributing to fuel efficiency and sustainability.

By Application

Interior Applications

Carbon fibre is extensively used in aircraft interiors to enhance aesthetics, reduce weight, and improve passenger comfort. Applications include seats, overhead bins, cabin walls, and flooring. The lightweight nature of carbon fibre helps airlines achieve significant fuel savings while maintaining high standards of interior design and safety.

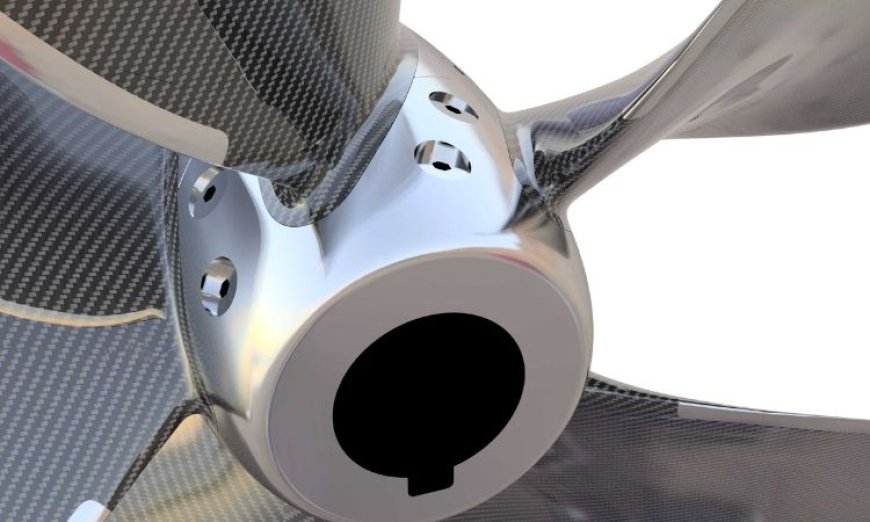

Exterior Applications

The exterior applications of carbon fibre in aerospace are critical for improving the performance and efficiency of aircraft. Carbon fibre composites are used in the construction of wings, fuselages, tail sections, and other primary structures. These components benefit from the high strength-to-weight ratio of carbon fibre, which allows for greater payload capacity and improved fuel efficiency.

By End Use

Commercial Aircraft

In the commercial aviation sector, carbon fibre is essential for building lighter, more fuel-efficient aircraft. Airlines benefit from reduced operational costs and lower emissions, aligning with global sustainability goals. The increasing production of commercial aircraft, driven by rising passenger demand, further boosts the demand for aerospace carbon fibre.

Military Fixed-wing Aircraft

Military aircraft require materials that offer exceptional strength and durability. Carbon fibre meets these requirements, making it a preferred choice for manufacturing various components of military fixed-wing aircraft. Its use enhances the aircraft's performance, reduces radar cross-section, and provides strategic advantages in defense applications.

Others

Beyond commercial and military aircraft, carbon fibre is used in various other aerospace applications, including unmanned aerial vehicles (UAVs), space vehicles, and helicopters. These applications benefit from the lightweight and high-strength properties of carbon fibre, contributing to improved performance and efficiency.

Market Dynamics

Drivers

- Technological Advancements: Innovations in carbon fibre production and composite manufacturing techniques are driving market growth.

- Rising Demand for Lightweight Aircraft: The need for fuel-efficient and environmentally friendly aircraft is increasing the adoption of carbon fibre.

- Expansion of the Aerospace Sector: The growth of both commercial and military aviation is boosting the demand for aerospace-grade carbon fibre.

Restraints

- High Production Costs: The cost of producing carbon fibre remains high, posing a challenge to its widespread adoption.

- Supply Chain Challenges: Ensuring a consistent supply of high-quality carbon fibre materials can be challenging.

Opportunities

- Innovations in Composite Materials: Ongoing research and development in carbon fibre composites are opening new application areas in aerospace.

- Emerging Aerospace Markets: Growing aerospace industries in emerging markets present significant opportunities for market expansion.

Challenges

- Competition from Alternative Materials: The development of alternative lightweight materials may pose a threat to the dominance of carbon fibre.

- Regulatory and Environmental Concerns: Meeting stringent regulations and addressing environmental impacts are critical challenges for the market.

Competitive Landscape

Key Players in the UK Aerospace Carbon Fibre Market

Several companies are leading the aerospace carbon fibre market in the UK, including notable names like Hexcel Corporation, Solvay, and Toray Industries. These companies are at the forefront of innovation, continuously developing advanced carbon fibre products to meet the evolving needs of the aerospace industry.

Market Positioning

A comparative analysis of key players reveals strengths, weaknesses, opportunities, and threats (SWOT). Companies are focusing on strategic partnerships, mergers and acquisitions, and research and development to strengthen their market position and gain a competitive edge.

Future Outlook (2024-2032)

Market Growth Projections

The UK aerospace carbon fibre market is expected to witness substantial growth, with a projected CAGR of 8.3% from 2024 to 2032. This growth is driven by the increasing demand for lightweight and efficient aircraft, advancements in carbon fibre technology, and the expansion of the aerospace sector.

Emerging Trends

Technological advancements in carbon fibre composites and the development of new applications in aerospace are key trends shaping the market's future. The adoption of sustainable materials and practices in aerospace manufacturing is also gaining traction, further boosting the demand for carbon fibre.

Strategic Recommendations

To capitalize on the growth opportunities, market players should invest in research and development, focus on reducing production costs, and explore new applications of carbon fibre in aerospace. Collaborating with aerospace manufacturers and engaging in strategic partnerships can also enhance market presence and drive growth.