Exploring Double-Sided PCBs: Benefits, Applications, and Fabrication Insights

Flexible PCB Fabrication is the manufacture of printed circuit boards that are capable of twisting, bending, and folding. As opposed to hard PCBs, they are manufactured using plastic substrates that are flexible, like polyimide, and molded into small and irregular space areas.

The world of electronics is changing very fast, and for that purpose, it requires a board that is capable of tolerating close-form designs, increased reliability, and flexibility of use. Flexible PCB Fabrication and Double-Sided PCBs are two of the key technologies driving this change. They are now an integral part of modern electronic design, whether in consumer electronics or aerospace systems. Understanding their structure, benefits, and use is vital to businessmen and engineers eager to keep pace with the electronics market.

What is Flexible PCB Fabrication?

Flexible PCB Fabrication is the manufacture of printed circuit boards that are capable of twisting, bending, and folding. As opposed to hard PCBs, they are manufactured using plastic substrates that are flexible, like polyimide, and molded into small and irregular space areas. This flexibility has made them a requirement in other sectors such as medical devices, automotive electronics, and wearable technology.

Its manufacturing technique is done by depositing conductive copper traces on a flexible substrate by which them can exhibit good electrical performance even under stress. Flexible PCBs have rendered rigid PCBs unnecessary in devices where high functionality and compact designs are needed.

Advantages of Flexible PCB Production

Flexible PCB Fabrication advantages reach well beyond simple space reduction. These boards have the potential to reduce the use of connectors and harnesses, lower weight, and simplify assembly. They also provide greater ruggedness through their resistance to vibration and dynamic motion, rendering them ideal for high-performance and mobile systems.

Flexibility in design is also a virtue in this model. Electronics designs comprise the ability to make circuits that will fold into new forms so that products can be reconfigured. Aerospace and consumer electronics industries thus predominantly use flexible PCBs to design more efficient and lighter products.

Learning Double-Sided PCBs

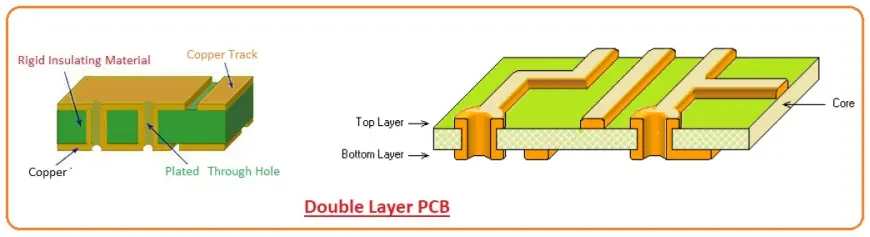

Whereas flexible PCBs provide flexibility, both-sided PCBs are aimed at introducing features and circuit density. Unlike single-sided boards where the conductive pattern is on one side, in two-sided designs, the copper shows up on either side. That allows for more complex and denser circuitry in the same board size.

These employ plated-through holes (PTH) to interconnect traces on either side to accommodate advanced components as well as signal routing. Both-sided PCBs are used extensively in power supplies, LED lighting systems, control panels, as well as in machines for industrial automation.

Benefits of Both-Sided PCBs

The most important advantage of the Both-Sided PCBs is that more complex circuits can be accommodated on the same-sized board. This makes them an economical option for applications of moderate complexity for which single-layer boards are suitable in just a few applications. The through-hole offers good mechanical reinforcement and electrical connection, enhancing the overall reliability.

Also, these boards achieve the perfect compromise between price and performance. They offer more circuit density than one-layer PCBs without being as pricey as multi-layer PCBs, thus a suitable option in most businesses.

Uses of PCB Manufacturing and Both-Sided PCBs

Flexible PCB Production can be used in advanced technologies such as foldable smartphones, implantable medical devices, and advanced vehicles. Such PCBs are used in cameras, hearing aids, and other small devices requiring light yet stiff solutions.

Conversely, Both-Sided PCBs are used in power conversion equipment, testing devices, HVAC systems, and lighting LEDs. They are appropriate for applications involving moderate complexity and without the extra expenses of multi-layer technology. Such technologies combined form the foundation of modern electronic design and can be applied across many industries.

Challenges in Fabrication

Flexible PCB Manufacture and both-Sided PCBs both have challenges. Flexible PCBs are susceptible to damage and deformation when they are being manufactured. Their assembly requires the soldering process to be precise because the substrate is flexible. Alignment of layers is imperative. Drilling and plating of the through-holes need to be precise to provide good electrical contact. Contractors need to have a high quality to deliver functionality and longevity.

Conclusion

In the current era of electronics, Flexible PCB Manufacturing and Double-Sided PCBs are key points that decide innovation and efficiency. Although flex boards offer unparalleled flexibility and mobility, two-sided PCBs offer enhanced circuit density with an affordable cost. Engineers and enterprises have to remain mindful of the requirements of the particular business applications in order to select the best solution. With alliances with trusty manufacturers, such as LYRTION, organizations interested in remaining competitive in the electronics industry can be assured of PCB services according to the latest industry standards.

FAQs

Q1 What is used in PCB Fabrication?

The flexible PCBs are typically constructed using polyimide or polyester panels because of their flex resistance and resistance to heat.

Q2. Are Double-Sided boards more expensive than single-layer boards?

Double-sided PCBs are more expensive than single-sided PCBs, considering they're more complex, but cheaper than multilayer PCBs.

Q3: Which are the most advantageous industries to PCB Fabrication?

Medical devices, automotive, aerospace and consumer electronics are some of the most advantaged industries due to the compact and rugged designs required.

Q4: What is the interaction between the two sides of a Double-Sided PCB?

The two layers are held together by plated through-holes (PTH) through which the electrical signals may pass.

Q5. Will Flexible PCBs replace rigid PCBs?

Not exactly. Although Flexible PCBs are very flexible, rigid PCBs would still be used in applications that require stability and low cost.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0